Aluminium casting plants

Get high quality aluminum for parts manufacturing

Our smart casting plants, meet the exigent market specifications for complex and top quality aluminium components.

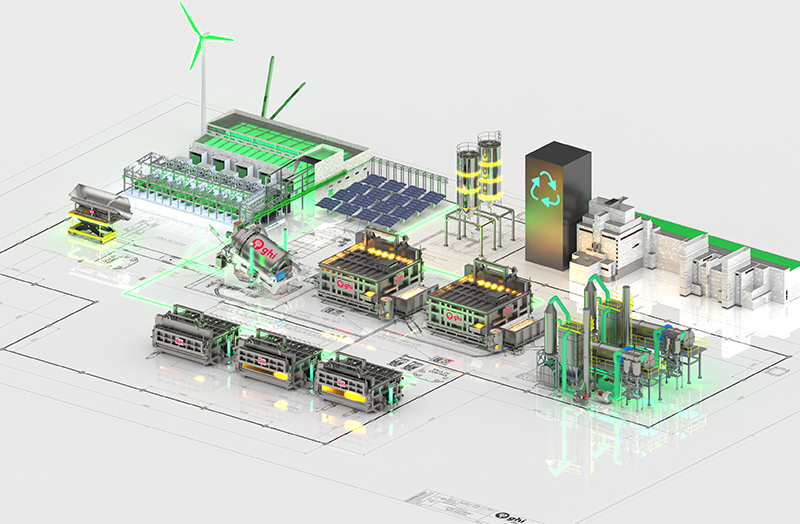

PRIME is the fully automated solution for casting plants, with guarantees of minimum energy consumption and metal yield over 99,5%*. We develop integral solutions together with our customers to increase the profitability and efficiency of their aluminium casting plants, fully integrated in the 4.0 industry.

*With primary aluminium ingots as raw material

High performance and

sustainable casting plants

Automatic skimming machine

Allows the automation of the cleaning and skimming process of the melting towers and holding furnaces, resulting in high quality metal and minimum maintenance costs.

Continuous loading system

Provides autonomy to the continuous loading process of ingots and/or baskets, thus increasing the productivity and efficiency of the furnaces.

Melting tower

The most efficient furnace for melting aluminum ingots and medium size returns, with metal yield exceeding 99%.

Reverberatory holding furnace

Specifically designed for receiving, holding, alloying and preparing high quality aluminium.

The key equipment of the PRIME plants are the melting towers, with high perfomance and energy efficiency, designed for melting ingots, returns or medium size clean scrap.

Its operating principle is based on the heat transmission from the combustion fumes to the aluminium that is loaded through the top of the hopper. As the fumes pass through the aluminium load, it is heated, dried and finally descends to the bottom of the tower, where it is completely melted.

The cleaning door of our melting towers, covers the entire width of the melting chamber, and together with the automatic skimming system, allow an easier and safer accesibility and therefore an improved cleaning operation. This results in high quality aluminium, lower maintenance costs and a longer life-time of the furnace.

Our smart plants include auxiliary equipment, such as loading systems and skimming machines that improve and make easier the operation of the plant.

The molten aluminium from the melting tower is transfered to the holding furnaces, where it is alloyed and the chemical composition is homogenised.

Finally, the metal is poured into transport ladles to continue with the next steps of the casting process.

The Prime Casting plants are completely Smart and designed to be integrated in the 4.0 Industry with the Beyond platform.

Digitized plants

We incorporate 4.0 industry solutions, offering equipment with the

latest technology and Smart Maintenance Service.

Value proposal

Maximum metal yield

Energy efficiency

High productivity

Safety for workers

High quality aluminium

4.0 Industry

Are you looking for a partner that guarantees you a full service?

Miguel Ugalde

Manager, MAPSA

“We have full confidence in GHI technical solutions. We highly value the personalised service that we have always received since we started working together in 1968.”