New aluminium billet manufacturing plant in Mexico

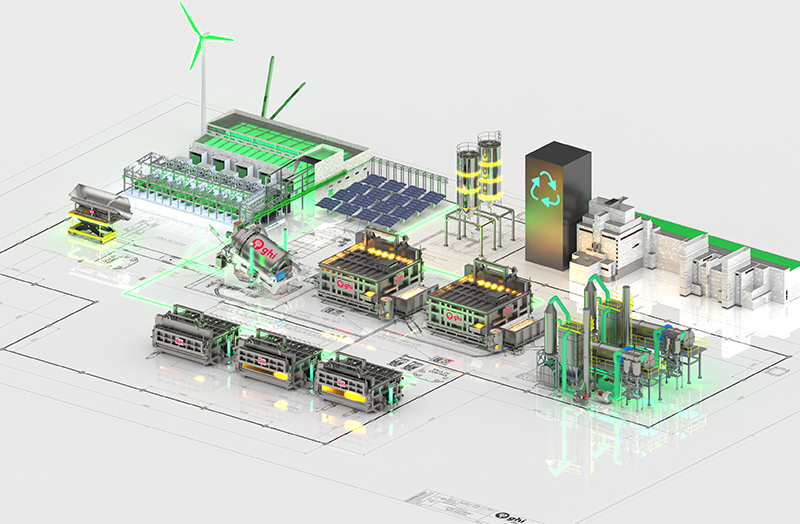

This project consists of a complete plant for aluminium billet production, that was developed in two phases. The first phase included the equipment for aluminum melting, casting and billet homogenizing with a production capacity of 20,000 tons per year and was officially inaugurated in May 2019. In the second phase the production capacity of the plant was doubled to 40,000t/year by adding new equipment.

Integral solution

This project was developed in two phases. The first phase consisted of a plant for melting, casting and homogenizing aluminum billets with a production capacity of 20,000 tons per year and was inaugurated in May 2019. In the second phase the production capacity of the plant was doubled to 40,000t/year by including new pieces of equipment.

First phase

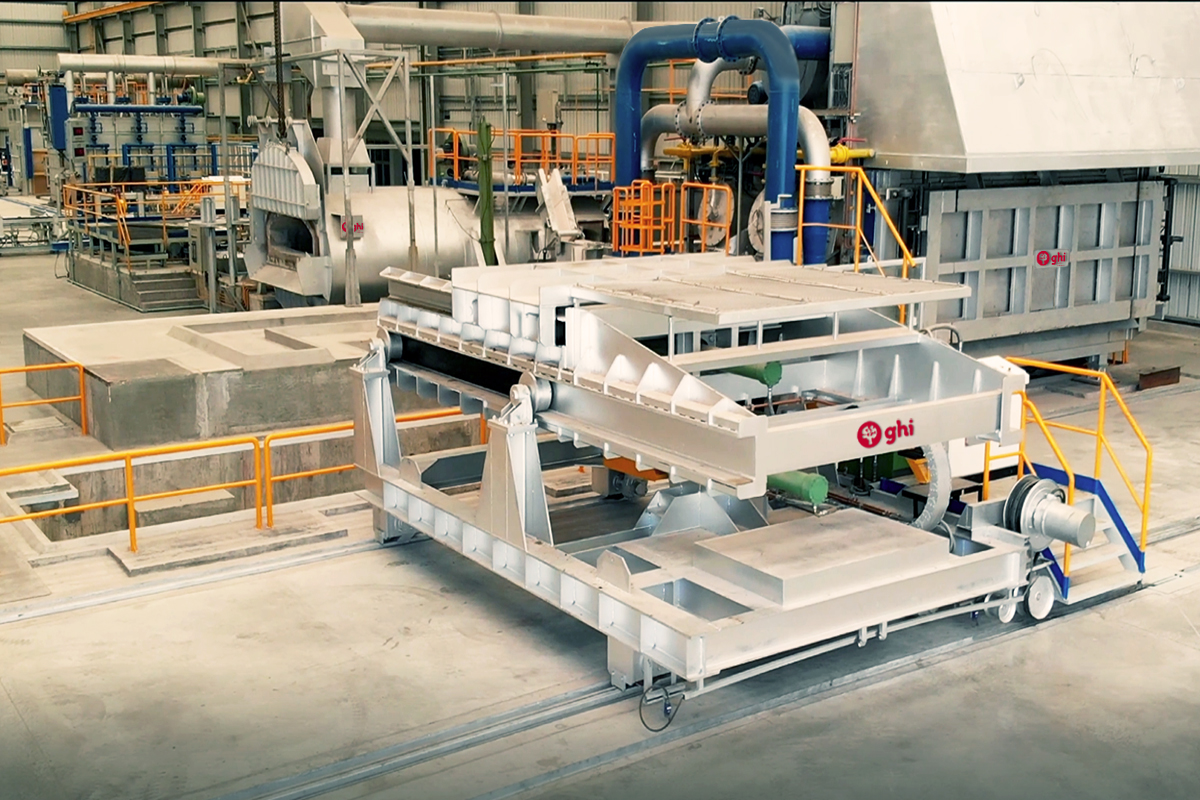

The first phase of the project consisted of the engineering, supply, installation and commissioning of the equipment for aluminum melting and homogenizing aluminum billets, as well as the casting machine. There was installed a 25-ton capacity reverberatory melting furnace with regenerative burners. The 6t/h melting furnace has an open front which allows a fast and efficient loading of the raw material and allows the skimming process to be carried out efficiently. The combustion equipment with regenerative burners reduces energy consumption and environmental impact, which is one of the main goals of our client.

Additionally, there was installed a 25-ton reverberatory holding furnace equipped with porous plugs, in order to adjust the alloy and hold the liquid aluminium. The installed porous plugs increase the uniformity of the temperature in the aluminium bath and achieve optimal homogeneity level of the chemical alloy of the aluminium.

The billets are then casted on a vertical casting machine, which is also supplied by GHI, thus ensuring the final quality of the product.

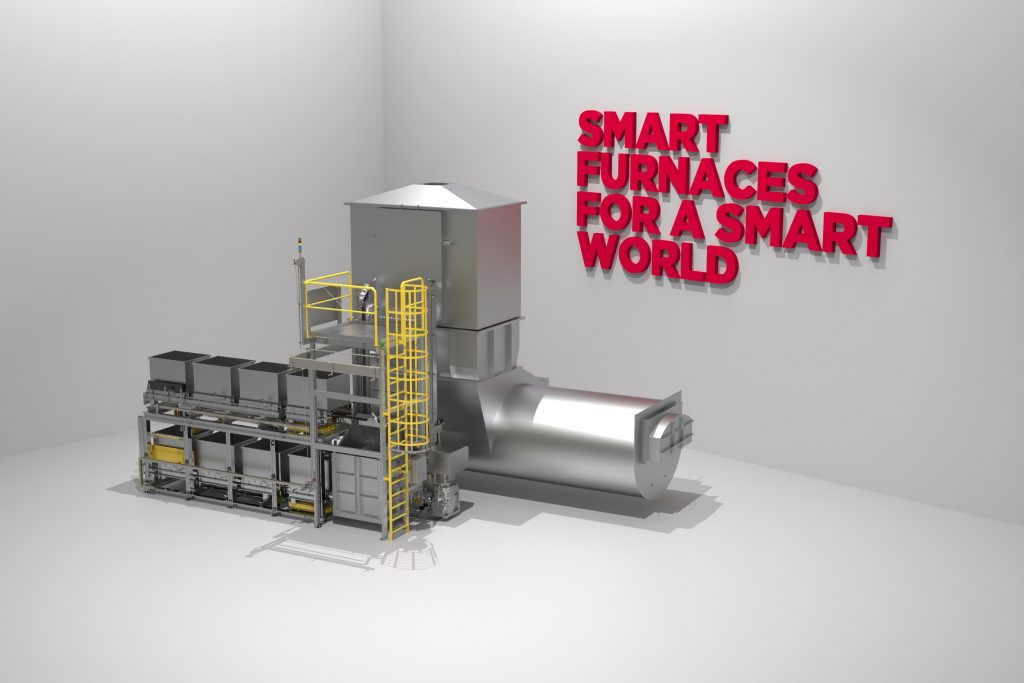

In addition, GHI supplied 25-ton capacity heat treatment furnaces for homogenizing billets equipped with a loading machine. This type of furnace has the advantage that only the load absorbs heat inside the furnace, since there are no supports or trolleys that in other cases are at least partly heated up and cooled with the load, which means an energy loss that slows down the treatment and makes it more expensive.

Lastly, the billets are cooled in a controlled manner in a cooling chamber of the same capacity. The cooling chamber has a serie of fans in its roof that blow the air across the load, similarly to air in the heating furnace.

Second phase

In this phase, the production capacity was doubled in order to reach 40,000 t/year. For this purpose there were installed a 25-ton reverberatory melting furnace and a 40-ton billet homogenizing furnace including a loading machine and a cooling chamber.

These new equipment made it possible to double the melting rate and heat treatment capacity in order to achieve the objectives set by our client.

Advantages

- Reduction of energy consumption and environment impact.

- Fast and efficient charging in the melting furnace

- Optimum levels of homogenity in the chemical alloy of aluminium, thanks to the porous plugs in the reverberatory furnace.

- Use of state-of-the-art regenerative burners with high efficiency

- The homogenizing furnaces heat only the load, which achieves great energy savings

- Process automation

- High quality billets