Auxiliary Equipment for Iron and Steel

List of auxiliary equipment

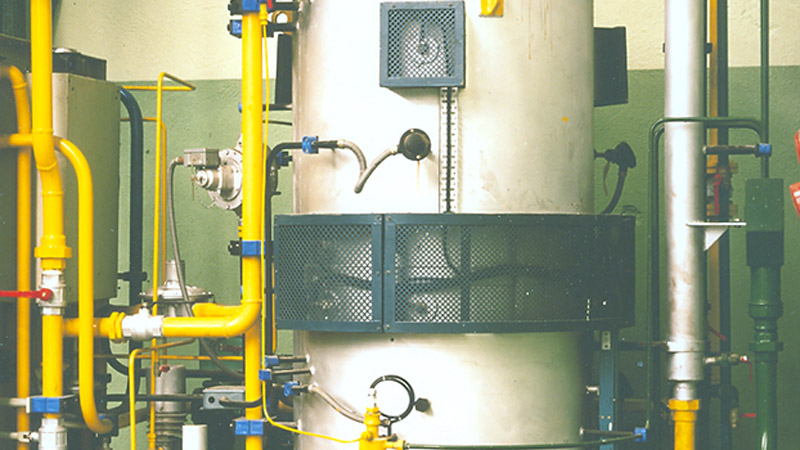

Atmosphere generators

Certain treatments need to be carried out in a furnace with a specific atmosphere. Atmosphere generators enable this atmosphere to be created.

Their use:

– Prevents the surface oxidation of metals caused by the surrounding air, vapours generated by the lubricants used in rolling, etc.

– Causes surface chemical changes such as hardening, nitriding, carbonitriding, bluing, etc. in all types of steel.

The atmospheres generated are, in the majority of cases, exothermic or endothermic reactions of a gas, followed by the elimination or not of one of its components, such as H2O, CO2, CO, etc.

Operation

Exothermic atmosphere generators (FG):

These are obtained by partial combustion of a primary gas (natural gas). Their basic components are equipment for metering, premixing and compressing air and primary gas, a combustion chamber with one or more burners, a water-cooled gas cooler and a combustion water purging device.

Exothermic atmosphere generators without CO2 (NG):

These are obtained by wet or dry elimination of carbon dioxide from an exothermic gas. In both cases, water vapour is also removed.

They are used for heat treatment of alloy steels.

Endothermic atmosphere generators (DG):

These are obtained by thermal dissociation of a blend of air and a suitable primary gas (natural gas, propane, etc.). This dissociation takes place in a retort, inside which there is a reaction catalyst which is heated externally by electric elements or gas burners until reaching the required reaction temperature. Their basic components are equipment for metering, premixing and compressing air and primary gas and a retort with catalyst, arranged inside a furnace with automatic temperature regulation and a water-cooled gas cooler. They are used for heat treatment of medium and high carbon steels. Enriched with metered amounts of primary gas (natural gas, propane, etc.), they are used for quenching, hardening, sintering, etc. If ammonia gas is added, carbonitriding atmospheres are obtained.

Ladle heaters

Equipment used to preheat ladles prior to casting iron and steel.

Heater types

– Inverted ladle heaters, for small casting operations.

– Vertical heaters, with the ladle in its normal working position.

– Horizontal heaters, with the ladle at a 90º angle.

Value proposition

Prevents loss of casting temperatures.

Increased plant efficiency.

Prevents thermal shock between ladle refractory lining and molten metal.

| Capacity | As per customer requirements |

| Heating | Gas, electric or combined gas-electric |

Transport trolleys

Used to move steel ladles.

Operation

Trolleys fitted with different numbers of pairs of wheels, depending on the load to be moved.

Value proposition

Robust design with optimised maintenance.

Automated process, requiring less human involvement.

| Capacity | As per customer requirements |

| Operating mode | Manual or self-activating |

Loading machines

Loading machines serve the different furnaces and equipment in the installation.

These machines may move along rails embedded in the floor, or be mounted on overhead gantries, and/or move up and down to/from quenching tank, etc. The most suitable configuration is studied for each installation and layout.

They operate automatically and enable loads to be handled precisely, quickly and safely.

Operation

Transfer, entry, extraction, turning, raising and lowering movements are carried out by electromechanical and/or hydraulic mechanisms, operated by the installation control system.

Value proposition

Robust design with optimised maintenance.

Automated process, requiring less human involvement.

| Capacity | As per customer requirements |

| Drive | Electromechanical and/or hydraulic |

| Hydraulic power unit | One for supplying power to hydraulic components |

| Operating mode | Manual, from control desk, or automatic |

Quenching tanks

Rectangular-shaped devices designed for each application and size depending on part to be treated and quenching liquid used. Parts are quenched in them to achieve the desired metallurgical transformation.

Operation

The quenching liquid, which will depend on the quality desired for treated parts, is recirculated by agitators and/or agitation jets.

It may contain different liquids and is equipped with the appropriate control devices. Quenching quality can be measured by thermography cameras positioned at tank exit which take pictures of each part.

Value proposition

Quick, even quenching achieved using jets and/or agitators.

High-performance cooling through connection to external water cooling system.

Efficient filtration to extend service life of quenching tank and optimise operating costs.

| Capacity | As per customer requirements |

| Quenching media | Oil, water, water with polymers, salts |

| Liquid recirculation | By motor pump units |

| Cooling system | Plate heat exchanger |

| Heating system | Electric elements |

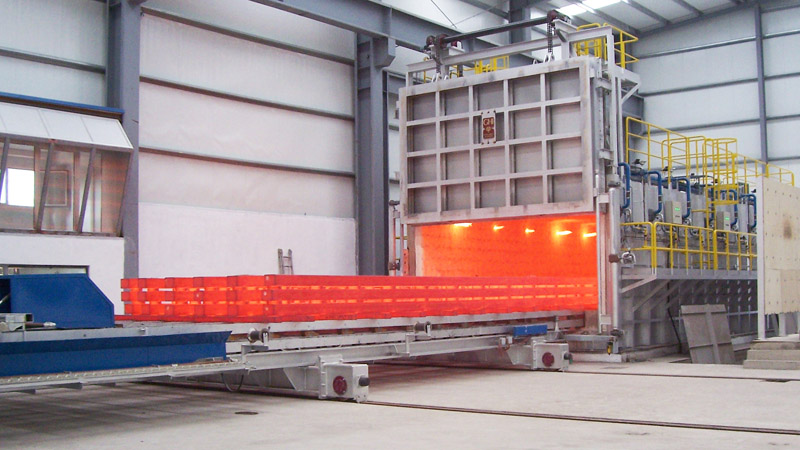

Load baskets

Steel containers used to load scrap into electric arc furnace.

There are two types:

Pincer handled using the auxiliary hook of the loading crane.

Segment: does not require auxiliary hook.

Operation

Solid metal is loaded into the top of the furnace, which is completely open when the vault has been moved, by means of these bottom-opening baskets which are moved by the crane and deposit the load directly into the furnace chamber.