Furnaces for Heat Treating Iron and Steel

GHI designs and installs a wide variety of furnaces for performing the most common treatments in the iron and steel industry, such as for example steel quenching and heating treatment of rolls, tubes, forged parts, cast parts, screws, nuts and bolts, large parts and diverse parts for the automotive industry.

Types of furnace for heat treating iron and steel

Installation designed for automatic holding of batch loads during different stages of each treatment.

Continuous furnace in which load moves forwards on a roller hearth, ensuring even treatment quality.

Furnaces able to treat large parts with different cross-sections and lengths, by means of loading and unloading equipment specifically for such parts.

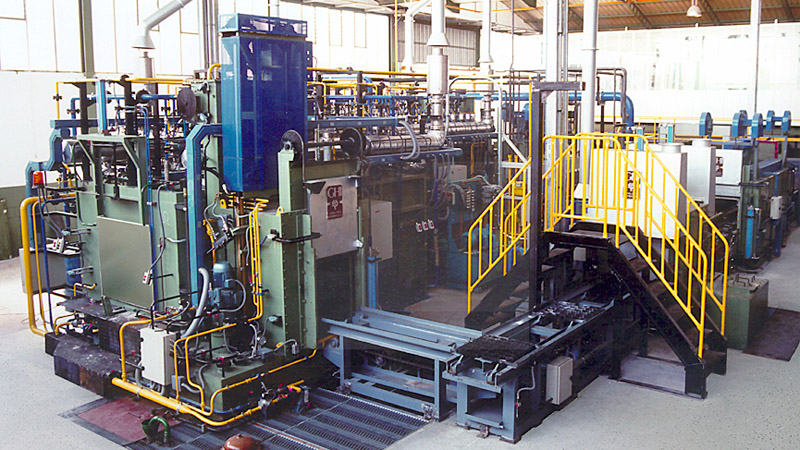

Continuous installations arranged in-line, with furnaces heated by natural gas combustion or electric elements, for quenching and tempering hardware.

Continuous or intermittent installations for heat treatments such as hardening, carbonitriding and quenching for the automotive industry.

High-performance installation able to perform a wide range of heat treatments with minimum transfer time between furnace and cooling tank.