Furnaces for Heat treating Iron and Steel Tubes

Flexible configuration of heat treatment

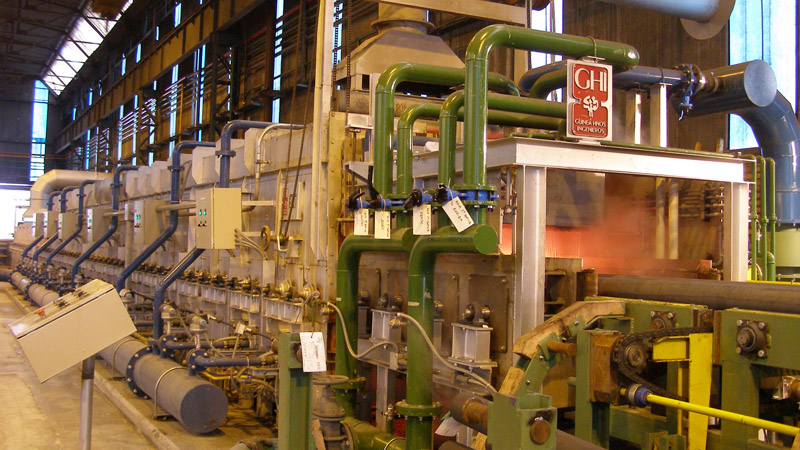

The installation comprises loading tables, furnace and unloading tables. Tunnel furnace with roller hearth. Inside the intake door, there is a zone where the iron or steel tubes are preheated by heat exchange with fumes from the main chamber.

Located immediately after the heating chamber is the cooling unit, the location and operation of which are critical since the water must act at a precise point, outside the exit door, and must not go back inside the heating chamber.

Operation

The furnace for iron and steel tubes is a continuous furnace. Loads are arranged on the relevant table, move through the inside of the furnace, and then exit onto the unloading tables. Load moves forward on rollers which rotate at a uniform speed, although it can be adjusted according to the treatment time required, which ensures even treatment quality and minimum workforce requirements.

Value proposition

High-precision temperature and uniformity across the entire load.

Fully automated installations.

Flexible configuration of heat treatments, according to customer requirements.

Certifications

Main features

| Capacity | According to customer requirements |

| Layouts | U-shaped or straight-line |

| Heating | Electric or gas |