Furnace for Heat Treating Iron and Steel Screws, Nuts and Bolts

Automated load handling and batching

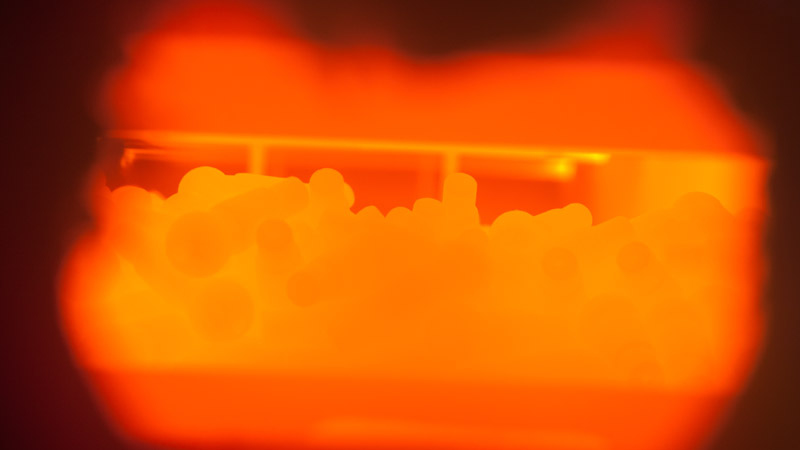

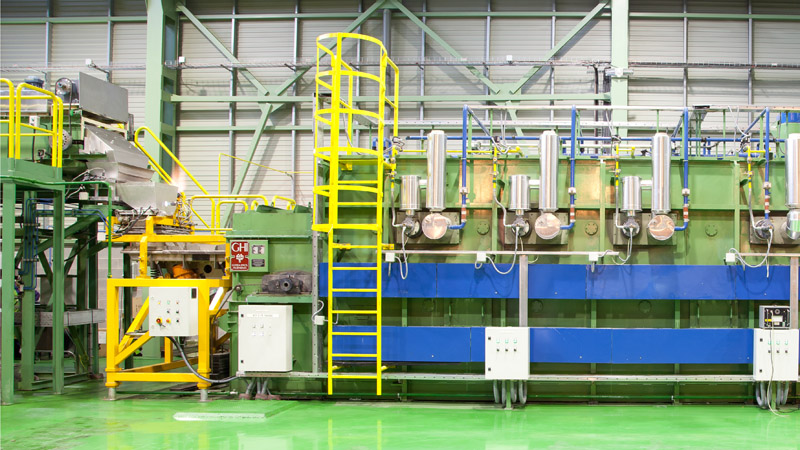

Continuous installations with in-line layout of components, furnaces heated by natural gas combustion or electric elements, used for quenching and tempering heat treatments of screws, nuts and bolts.

Lines are equipped with furnaces with mesh belt or cast link conveyors, usually a combination of both.

.

Operation

Lines usually comprise an automatic loading system, a prewash and drying machine with continuous conveyor, a heating furnace for quenching suitable for working in a protective atmosphere, with conveyor belt and radiant tube heaters, an oil quenching device with conveyor and a full set of liquid cooling and recirculation equipment, a washing and drying machine, and a tempering furnace fitted with fans and deflectors to ensure correct convection in the furnace chamber.

In some cases, and depending on the final finish required, the line can include a bluing polymer tank and/or water tank.

Value proposition

Fully automated load handling and batching.

Combustion equipment can optionally be fitted with heat recovery systems to reduce energy consumption.

Fully automated and monitored installation.

Uniform mechanical properties and homogenous structure.

Since furnaces fitted with cast link conveyors are hot belt furnaces, the conveyor does not exit the unit and cause heat losses.

Fewer temperatures changes on the conveyor, and therefore longer service life.

Optional inclusion of a hot intake system with atmosphere saver, allowing for lower consumption of protective atmosphere.

Mesh belt furnaces permit treatment of very small diameter screws.

Certifications