Furnace for Heat Treating Automotive Parts

High-precision load temperature and evenness

Continuous or intermittent installations for heat treatments, with furnaces heated by natural gas combustion or electric elements, used for heat treatments such as hardening, carbonitriding, quenching and tempering for diverse parts used in the automotive industry.

The automotive industry requires its suppliers to meet certain technical conditions when supplying thin parts, fasteners, etc. Some of these conditions have direct consequences for heat treatment installations, such as:

– Parts must be free from dents and physical flaws.

– The mechanical properties of batch materials, such as hardness and strength, must be uniform.

– The structure obtained in each part and each batch must be homogenous.

– Surface finish.

– Parts must be free from carburization or decarburization.

– Parts from different batches must be kept separate.

Operation

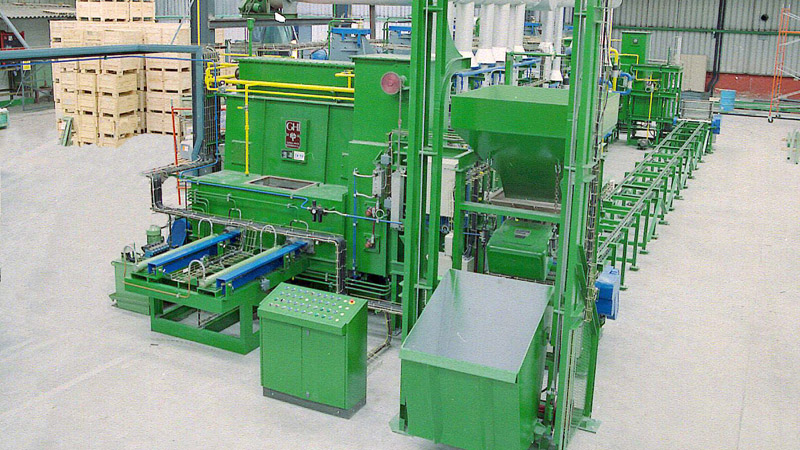

Similarly to heat treatment of screws, nuts and bolts, continuous lines usually comprise an automatic loading system, a prewashing and drying machine with continuous conveyor, a heating furnace for quenching suitable for working in a protective atmosphere, with conveyor belt and radiant tube heaters, an oil quenching device with conveyor and a full set of liquid cooling and recirculation equipment, a washing and drying machine, and a tempering furnace fitted with fans and deflectors to ensure correct convection in the furnace chamber. In some cases, and depending on the final finish required, the line can include a bluing polymer tank and/or water tank.

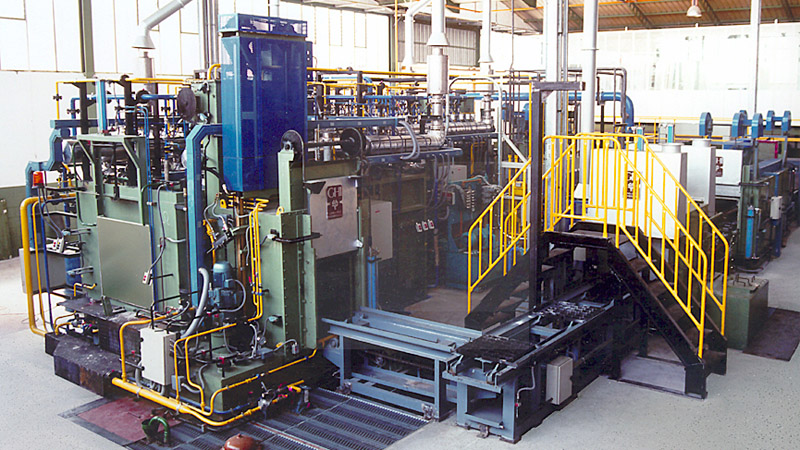

Where intermittent flexible units are used for heat treatment, the installation comprises:

– Chamber furnaces with built-in quenching tank.

– High and low temperature tempering furnaces.

– Burnoff furnaces for degreasing and preheating.br>– Washing machines.

– Load transfer and loading/unloading machines.

Value proposition

Fully automated load handling and batching.

Combustion equipment can optionally be fitted with heat recovery systems to reduce energy consumption.

Fully automated and monitored installation. Load batch traceability.

Uniform mechanical properties and homogenous structure.

Flexibility of heat treatments and production.

Certifications

Main features

| Capacity | As per customer requirements |

| Layouts | U-shaped or straight-line |

| Heating | Electric or gas |