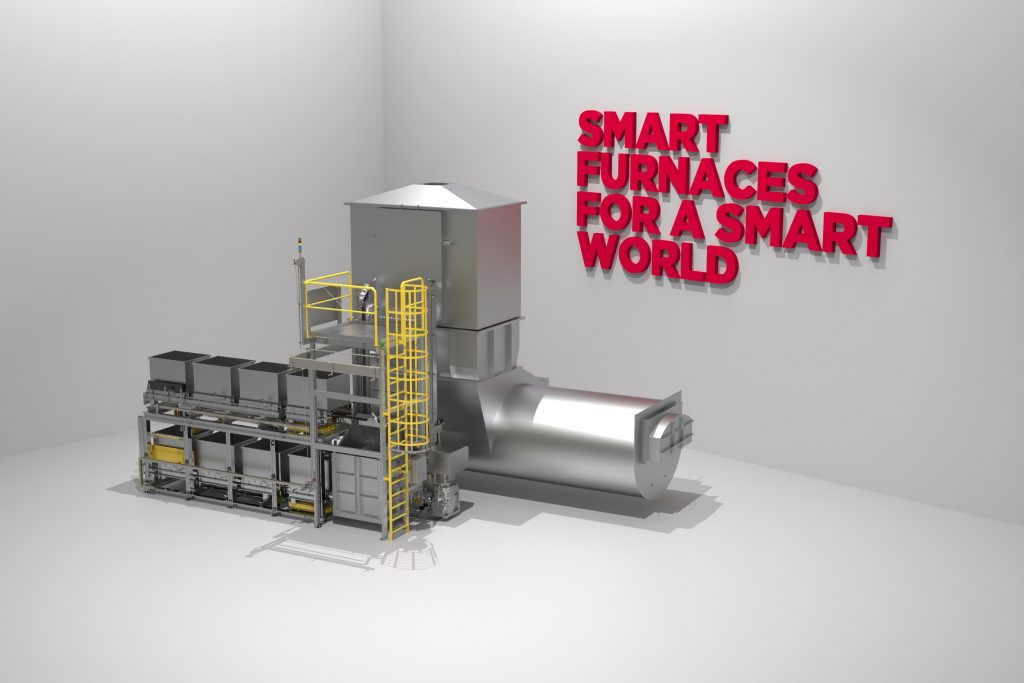

Tilting rotary furnace of 40 t and slag cooling system for Fundial, Spain.

GHI Smart Furnaces will supply a new 40-ton tilting rotary furnace together with a slag cooling system that will allow Fundial to double its aluminium ingot production capacity. This investment will enable Fundial to strenghten its position in the industrial market. It will also transform its existing plant in Legutio into a reference centre for the refinement and manufacture of aluminium ingots.

The commissioning of the equipment will take place in the first quarter of 2021.

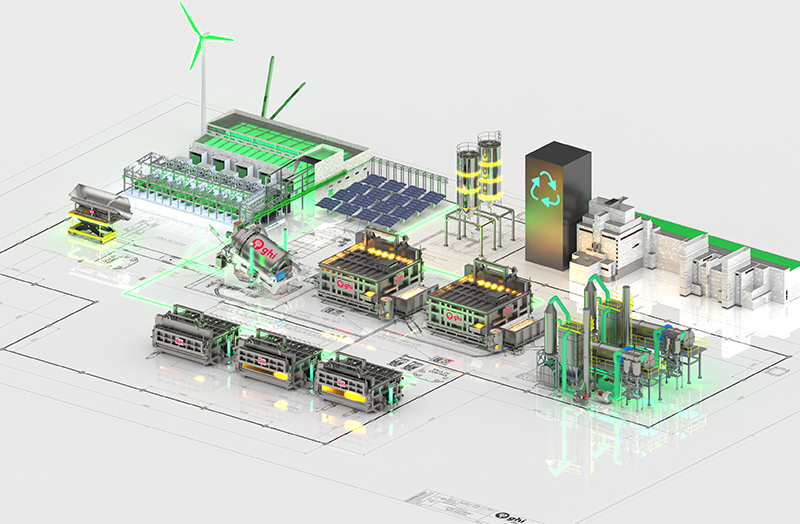

Integral solution

First of all, this expansion plan will provide Fundial with greater flexibility and variety in their aluminium alloy catalogue in order to meet the demands of each and every client in a personalised way. Moreover, the tilting rotary furnace and the salt slag cooling system supplied by GHI Smart Furnaces will allow them to be positioned as a low environmental impact aluminium foundry.

The 40-ton tilting rotary furnace is designed to achieve maximum metal yield from aluminium while keeping energy consumption to a minimum. This characteristic reinforces our value proposal for the efficient, low consumption technologies. In addition, the supplied furnace is suitable for all types of low-quality aluminium scrap, which will allow the company to expand its range of customers and suppliers.

Fundial will also extend its current assortment of alloys in order to meet specific requirements for greater hardness, conductivity or anti-corrosion.

The GHI salt slag cooling system maximises aluminium recovery from the salt slag coming from the tilting rotary furnace. This system quickly cools the salt slag preventing the oxidation of the aluminium. It also increases metal recovery and drastically reduces the space required for cooling compared to the traditional basket system.

The supplied equipment has a high technological component as it is specifically designed for the recovery of aluminium and the obtainment of a higher metal yield.

Both, tilting rotary furnace and the slag cooling system, will provide greater energy efficiency and lower CO2 emissions per ton produced.

Industry 4.0

In addition, the equipment supplied to Fundial by GHI Smart Furnaces will be integrated into Industry 4.0 under our BeyondAlea 4.0 platform. This platform includes advanced sensorization services, digitalization, technical assistance, process consulting and preventive maintenance.

All this will allow our customer to have a greater control over the production process and will significantly reduce consumption at the plant.

Ventajas

- Doubling of the production capacity

- Increased flexibility to process all types of aluminium scrap

- Maximum metal yield

- Slag cooling system that increases metal recovery

- Reduction of space required in the plant by removing slag cooling baskets

- Full compliance with safety and environmental regulations

- Integration into Industry 4.0 with advanced sensorization system and the BeyondALEA 4.0 platform