Aluminium recycling plants

Get the maximum aluminium recovery

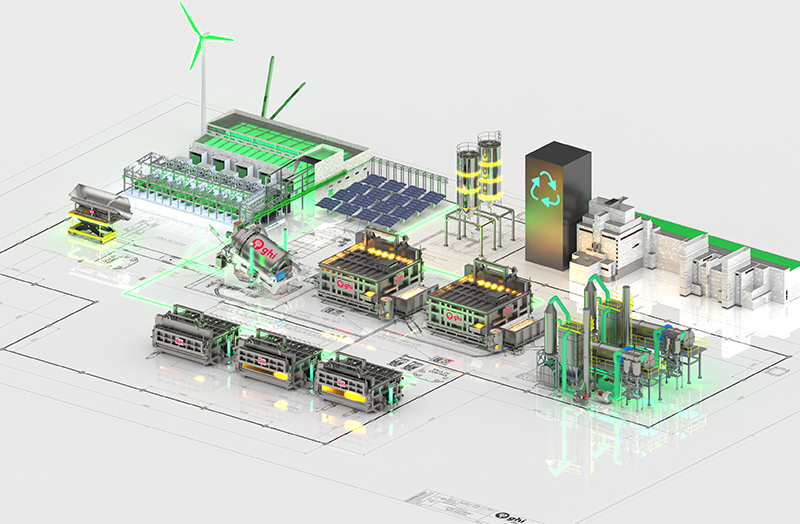

We supply fully automated and tailor-made turnkey plants, designed to obtain the highest metal yield with all kinds of aluminium scrap or dross.

We develop customized engineering projects along with our clients, in order to increase the profitability and productivity of their aluminium recycling plants.

New concept of

aluminium recycling plants

Salt slag cooling system

Via conveyor belts the salt slag is moved into the rotary cooling system, where it cools down safely, reducing the deslagging time by 80%.

Drying – Decoating system

Decoating / Drying system for shavings and fine-grade loads. Reduces metal losses, emissions and energy consumption in the melting process.

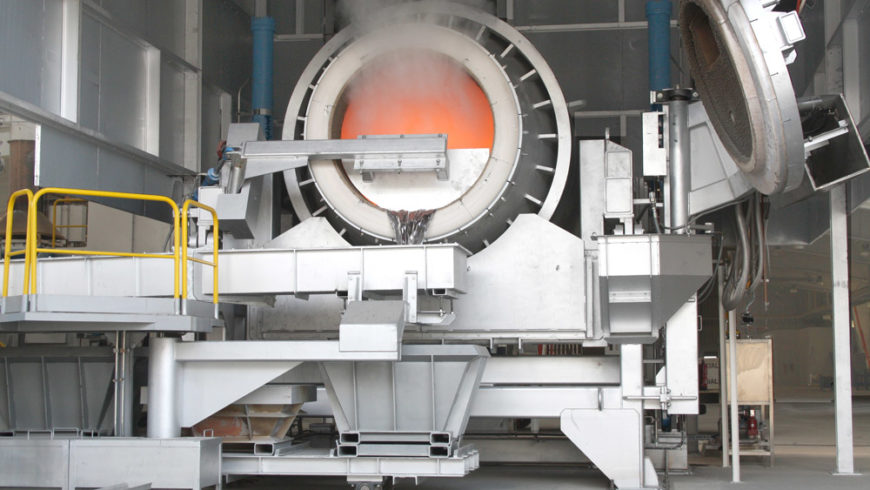

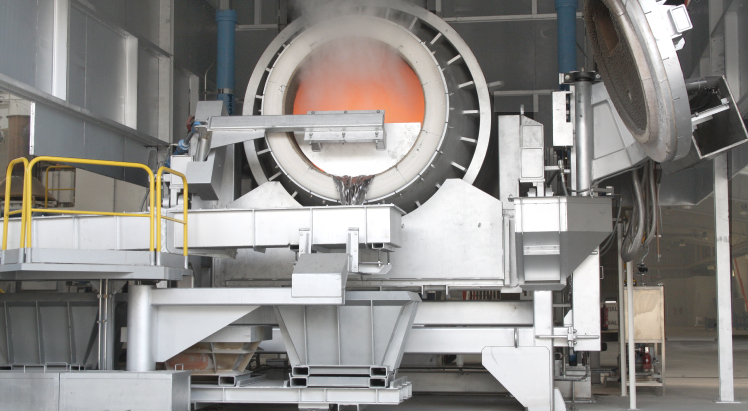

Tilting rotary furnace

Furnace for melting low-grade scrap and recovering aluminium from dross.

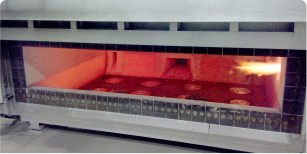

Reverberatory holding furnace

Specifically designed for receiving, holding, alloying and preparing molten aluminium.

Ingot casting machine

The ingot casting machine enables the production of aluminum ingots in a fast and profitable way, guaranteeing the uniformity in quality, weight and dimensions.

Vortex Furnace

Includes an agitation system that generates a vortex for melting fine-grade loads such as shavings, UBC, etc.

Transport ladles

Allows the storage and transport of liquid aluminium, ensuring its properties for many hours.

For chips or swarf as raw material, a drying and decoating system is used to obtain the maximum yield during the melting process in Vortex Furnaces.

If the raw material is dross or low quality aluminium scrap, this is melted in Tilting Rotary Furnaces. The resulting salt slag is then processed in the Cooling System. Once cool, it is transported through a system of automatic conveyor belts to silos where it is stored and, eventually, sent to salt slag recovery plants.

The molten metal obtained after melting is poured into Holding Furnaces, where the temperature and composition of the alloy are homogenized by means of Porous Plugs.

The final molten metal is poured into ingot molds or transport ladles for liquid aluminium.

Recycling of all types

of scrap and dross

Thanks to our specialized equipment, designed as per the latest technological standards, you will get the highest metal yield and will be able to supply the aluminium market with high quality products such ingots and liquid aluminium.

Highly contaminated scrap

Chips, briquettes and shavings

Slightly contaminated scrap

UBC

Dross

Would you like to increase the profitability of your plant?

Manuel Barrenechea

Director of Aluminium Division, Befesa

“In the last 5 years we have acquired 10 pieces of equipment from GHI that work satisfactorily and at full performance. In addition, we are working on a R&D project along with GHI and Tecnalia with the aim of improving the recycling process and make it even more automatic and efficient with 4.0 solutions.”

Digitized plants

We incorporate industry 4.0 solutions,

offering equipment with the latest technology and Smart Maintenance Service.

Value proposal

Highest

aluminium quality

Highest

metal yield

Higher productivity

and profitability

Safety

for workers

Sustainability

Industry 4.0

Tailor-made solutions

Continuous improvement

Are you looking for a partner that guarantees you a full service?

Julian Conde

Managing Director, REFIAL

“GHI provides outstanding engineering and technical assistance services”