Aluminium Wheel Rim Manufacturing Plant

Self-preparing alloy

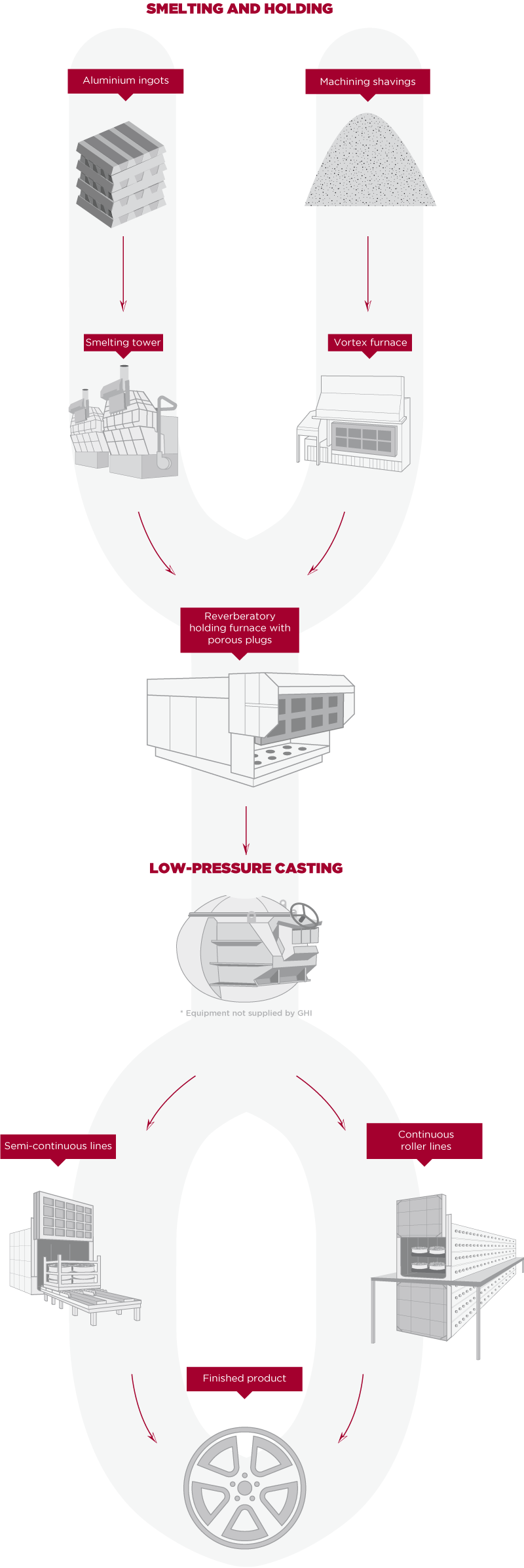

There are a number of stages in the manufacture of aluminium wheel rims: metal the metal, low-pressure casting, quality control, topping, heat treatment, machining and painting. The latest trend in this sector is self-preparing alloy. The process begins by smelting primary aluminium ingots with a low iron content in smelting towers.

The molten metal is then transferred to the reverberatory furnace fitted with porous plugs, where the alloying agents – principally silicon and magnesium – are added. Once the alloy has been certified, it is poured into ladles and taken to the low-pressure casting machines.

Heat treatment in 3 stages

After topping, the wheel rims undergo 3-stage heat treatment: solubilization, tempering and ageing. The treatment can be carried out on a semi-continuous line, where the rims are placed in steel containers, or in continuous roller facilities, where the rims are moved directly on the furnace rollers, avoiding the use of containers which have a negative impact on energy consumption, heating time and loading/unloading logistics.

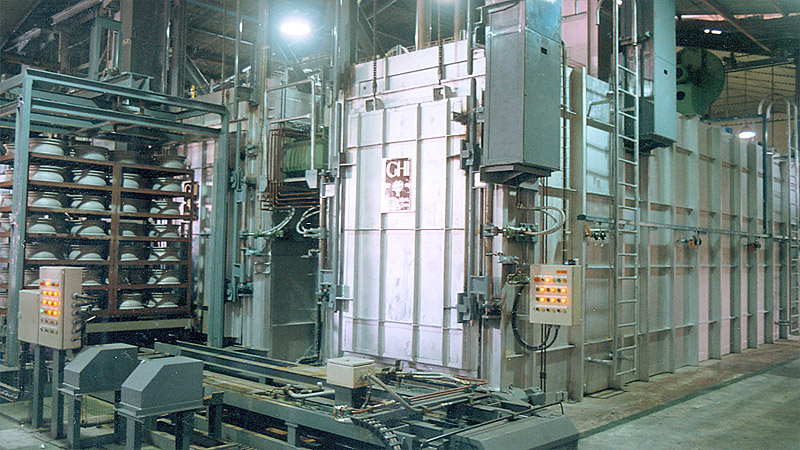

At GHI, we design and supply the furnaces and auxiliary equipment used in the production process, during both smelting and treatment.

Plant certifications

Wheel rim manufacturing process

Value proposition of this plant

Self-preparing alloy.

Good surface quality and dimensional precision.

Quality and uniformity of the aluminium recovered, through an agitation system using porous plugs or other systems in holding furnaces.

Jointly engineered by all the stakeholders in the process, the aim being to find the solution that best meets the customer’s current and future needs.

A high degree of process automation permitting high production levels and minimum human involvement.

A management and control system which permits process variables to be monitored, thus offering possibilities for control and continuous improvement.

Compliance with automotive sector requirements and certifications.

A high degree of process automation permitting high production levels and minimum human involvement.