The largest rotary furnace in the world

Befesa, one of the most important global companies in recycling salt slag and aluminium residues, needed a turnkey solution to increase the recovery of aluminium from low quality scrap, to achieve a high metal yield and full control of the aluminium melting process with low environmental impact. The new equipment will replace a fixed axle furnace with a low capacity and high salt and energy consumption.

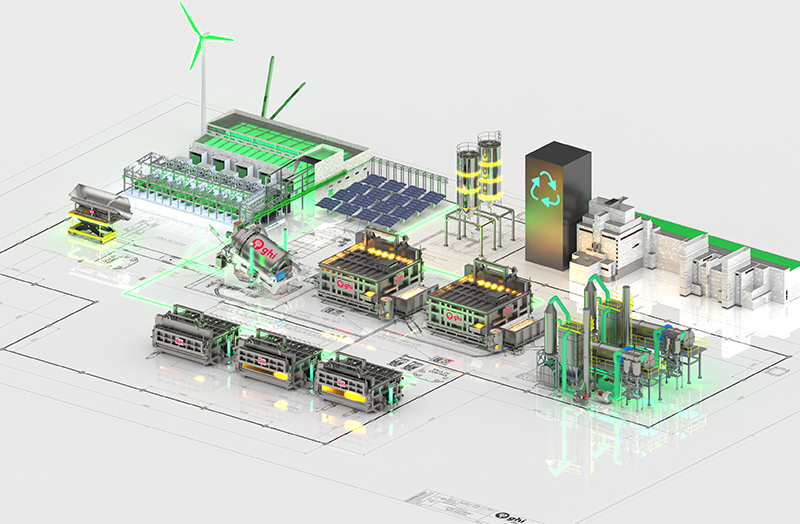

Integral solution

The limits in terms of required process time and available space in the plant required a furnace size never seen before in the industry. We supplied a 65 t tilting rotary furnace that exceeded the previous world record set by GHI, with a rotary furnace supplied to Fracsa Alloys, by 30%. The new equipment is the largest in the world to date, with a colossal size: 8.5 metres long, 5.5 metres high and 150 t in weight.

It is designed to recover aluminium from low quality scrap and to produce significantly less pollutant waste than traditional models. Its geometry facilitates the emptying and cleaning of the dross. In addition, its double-door system increases the energy efficiency and automation of the process.

The furnace will improve costs per tonne by replacing a fixed axle system with greater salt consumption and worse energy performance.

It is fully sensorized, it is capable of transmitting 1,000 values per second, analyzed by Big Data systems with Artificial Intelligence, controlled by our engineers. These algorithms allow the detection of the level of wear of the components, the prevention of unexpected stoppages and the planning of maintenance actions.

Advantages

- Higher recovery of aluminium contained in the dross

- Reduction in the cycle time

- Reduction in manual tasks in the plant

- High energy efficiency

- High level of automation

- Lower salt consumption

- Full integration with existing equipment

- Control of standardization and optimization of the aluminium recycling process

- Real time monitoring of the operations and detection of anomalies

- Remote technical assistance service