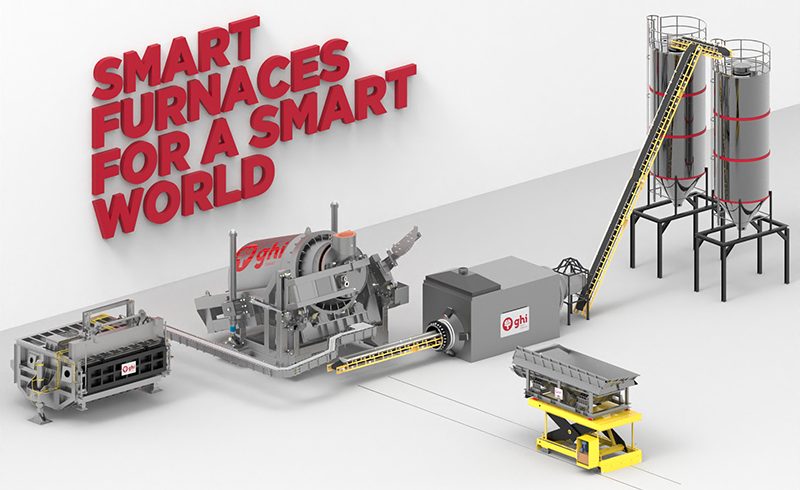

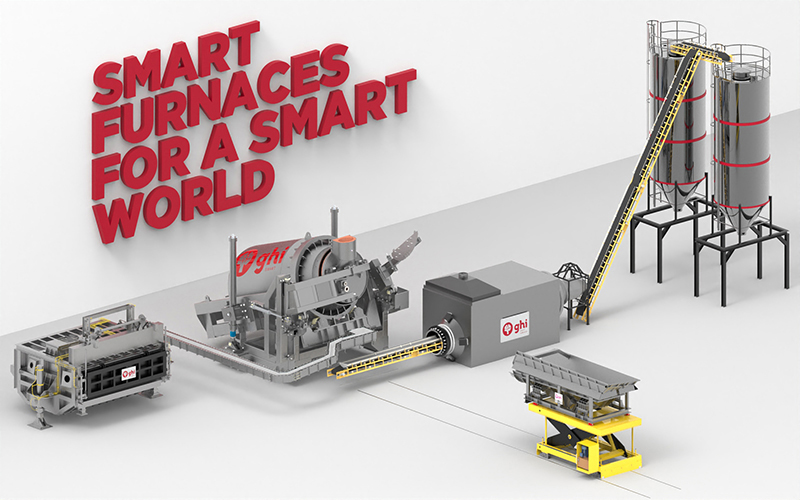

Almexa grants GHI Smart Furnaces the contract to supply the key equipment of its new casthouse in Veracruz (Mexico)

Almexa’s new casthouse will be the newest and most efficient in all America, it will be inaugurated in the second semester of 2021. The key process equipment will be supplied by GHI Smart Furnaces, a world leader in the furnaces industry. The plant will have the most advanced equipment for aluminium processing aimed to achieve a circular economy.

With a production capacity of more than 90.000 t/year, the plant will have the America’s largest tilting rotary furnace of 65 tons capacity, one of the for existing in the world and all supplied for GHI. It is specifically designed for aluminium recovery.

Additionally, a salt slag cooling system will be installed to achieve higher levels of metal recovery with low environmental impact. Furthermore, a high efficiency melting and holding furnace of 50 tons capacity with regenerative burners will be installed.

The new casthouse will be a world reference for the production of canstock, it is carefully designed to obtain high quality aluminium with an environmentally friendly process with full automation and smartization. The key equipment is completely sensorized, and the gathered data is analyzed with Big data and Artificial intelligence technological solutions leveraged in the Beyond Alea platform to improve the process productivity and control of the Smart Plant.

The tilting rotary furnace will work as the main melting equipment of the plant, the resulting aluminum will be transferred to a new melting and holding furnace where, additional melting capacity is installed and the alloy will be adjusted and then, it will be transferred to the vertical casting machine.