Steelworks

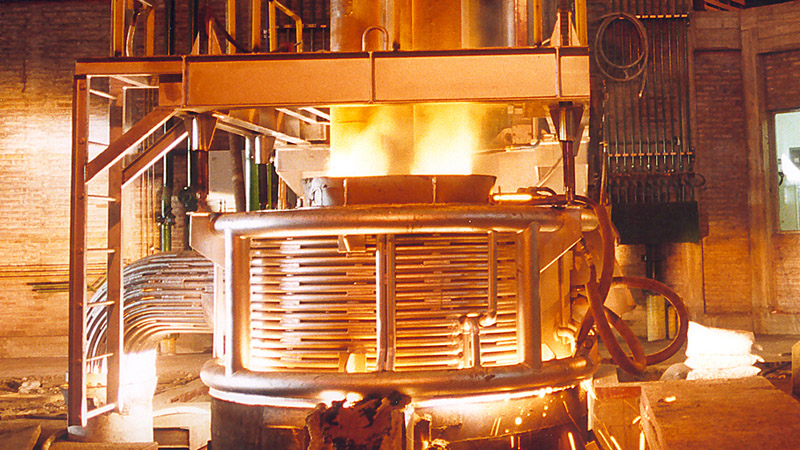

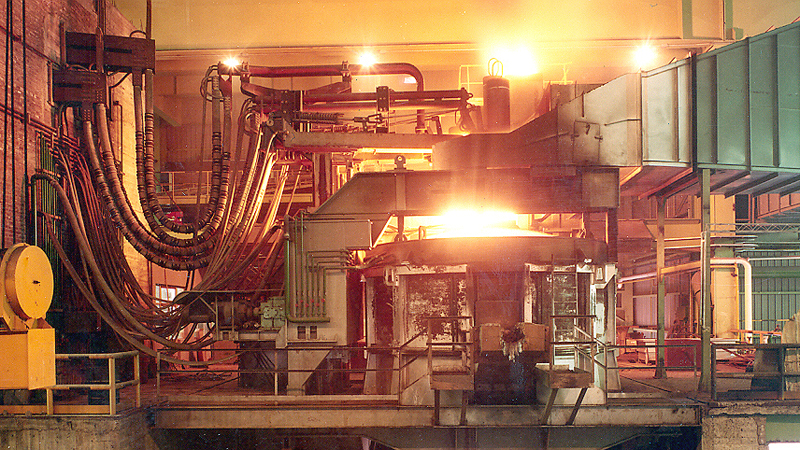

Commissioning and upgrading steelworks

Plants for producing large quantities of cast iron and molten steel, subsequently used to manufacture tubes, billets, ingots, bars, wire rods and large forged parts.

In addition to the melting area, these plants have highly automated heat treatment lines that only require worker involvement for the initial loading stage.

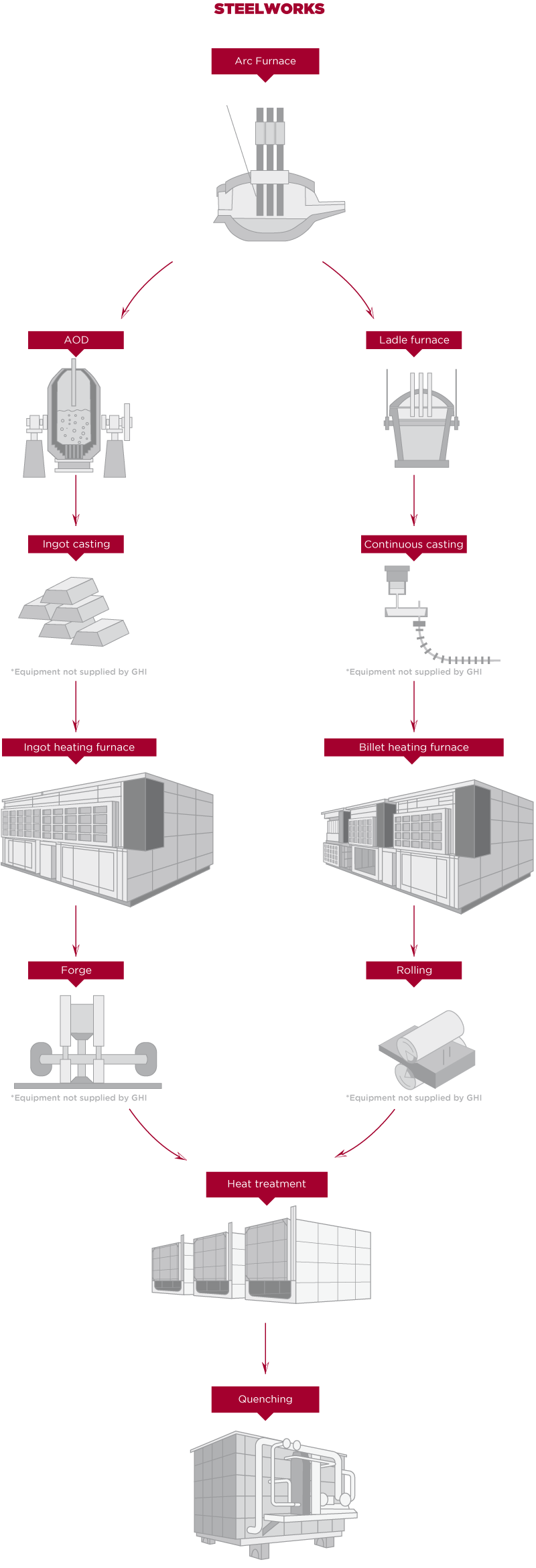

Steelworks process

Value proposition of this plant

GHI has extensive experience in commissioning and upgrading steelworks.

Energy and electrical parameter management systems and equipment for minimising refractory consumption and similarly consumption of electrodes and electricity, and for protection purposes.

Jointly engineered by all the stakeholders in the process, the aim being to find the solution that best meets the customer’s current and future needs.

Energy-efficient equipment.

A high degree of process automation permitting high production levels and minimum human involvement.

A management and control system which permits process variables to be monitored, thus offering possibilities for control and continuous improvement.

Corrective, preventive and predictive maintenance; SAT and Services 4.0.