Auxiliary Equipment for Aluminium

List of auxiliary equipment

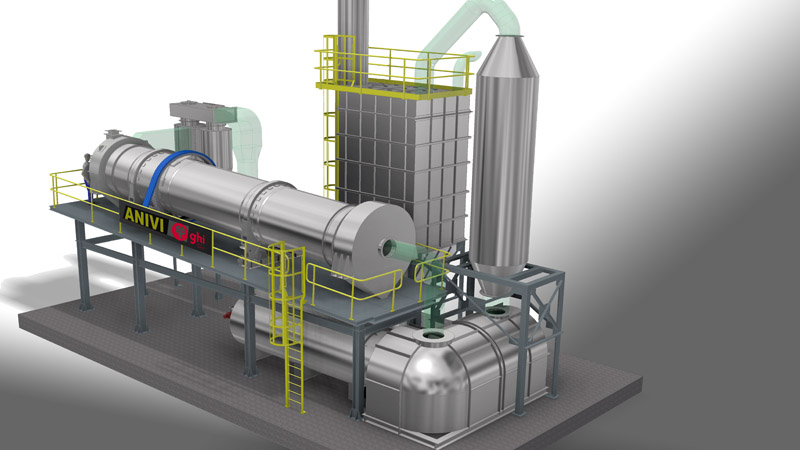

Salt slag cooling system

It is used to cool the salt slag used in rotary furnaces in aluminium recycling plants. The cooling system reduces the fumes emission and prevents the oxidation of the aluminium contained in the salt slag, thus increasing the metal recovery. Furthermore, it significantly reduces the plant space required this process.

Operation

The salt slag used in the rotary furnaces is poured into a dedicated conveyor and introduced into the trommel of the cooling system. The salt slag never gets in direct contact with the cooling water, which makes this system completely safe. Once the cooling cycle is completed, the dust and fines are transported to storage silos for further processing in salt recovery plants while coarse aluminium pieces are sent back to the melting furnace.

Value proposition

Higher metal yield due to the recovery of aluminium in the salt slag by preventing its oxidation.

Reduction of the required plant space by decreasing the amount of baskets by 90%.

Less environmental impact.

Improvement in plant safety.

Loading machines

At GHI, we have designed a series of machines for optimising the operation of furnaces and equipment.

Operation

These machines have a hydraulic power unit that supplies the drive fluid for load elevation, lowering and gripping. They work automatically, but can also be operated manually.

To monitor loading and unloading operations, the machines are equipped with video cameras which are of even greater usefulness when multiple furnaces are in operation.

Value proposition

Doors open for a shorter time.

Door lintel and threshold refractory linings last longer.

Greater efficiency of smelter, since there is less heat loss.

Improved worker safety, since the process is automated.

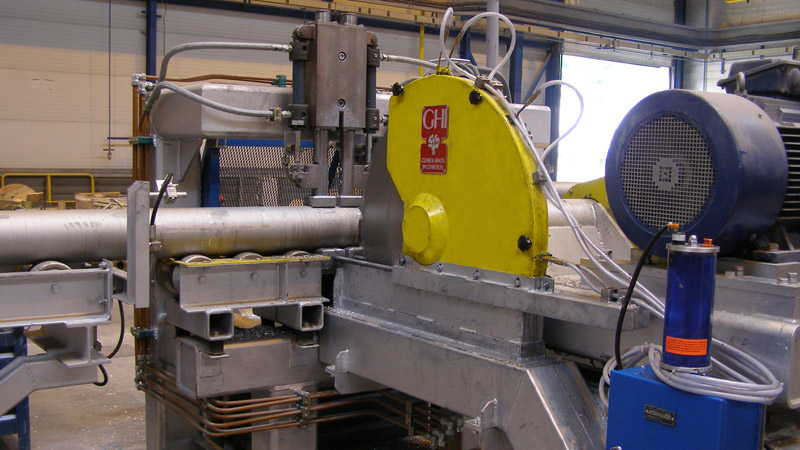

De-drossing machines

The quality of the metal obtained from the second melting operation depends on the cleanliness of the smelter and lack of dross in casting. Dross is removed by machines specifically for this purpose.

Operation

They have a movement trolley which enables them to be positioned anywhere along the width of the door opening. They have a second mechanism which enables a cleaning rabble to be inserted inside the furnace chamber, and cooling systems to prevent arm warping.

Depending on the application required, they may be floor or overhead-mounted, or move along embedded rails.

Value proposition

Optimum bath cleanliness.

High quality metal obtained.

Furnace refractory linings last longer.

Transport ladles

As an alternative to ingot supply, we can offer you ladles for transporting molten aluminium. These ladles are insulated, so transport time can be several hours without the metal requiring reheating.

Operation

Aluminium is supplied in 6-tonne capacity closed ladles.

Value proposition

Improved energy consumption.

Less loss of metal.

Metal does not require reheating.

A second mechanism allows for a cleaning wire to be inserted into the entire chamber. It includes a cooling system which prevents the wire mast from warping.

Porous plugs

By means of these plugs, an inert agitating gas, nitrogen and/or argon are blown into the bath.

Operation

They are located in the floor of the furnace. Bath agitation homogenises both temperature and chemical composition.

Value proposition

Reduced hydrogen content in the bath.

Enhanced cleanliness of bath.

Increased melting capacity of furnace.

Minimum operating cost.

Cooling chambers

These are used for controlled or non-controlled cooling of previously treated parts. They are sometimes used as an active part of the treatment, and sometimes to shorten the cycle time.

Operation

Cooling chambers have a series of fans in their roof which blow air across the load, similarly to air in the heating furnace. Around the fan housing area are cold air intakes with adjustable flow rates, so a greater or lesser volume of cold air can be drawn in according to the cooling speed required.

These chambers can have a water-cooled cooling system, in which case they will be manufactured from stainless steel.

Value proposition

Coil treatment process time is shorter.

Quenching tanks

These perform cooling of parts to give them the desired metallurgical transformation.

Operation

These tanks can hold different fluids and are fitted with the appropriate control equipment. Quenching quality is measured by two thermography cameras located at the tank exit, which capture thermographic images of all parts as they exit the tank.

Value proposition

Rapid, homogenous quenching is achieved through use of jet and agitator systems.

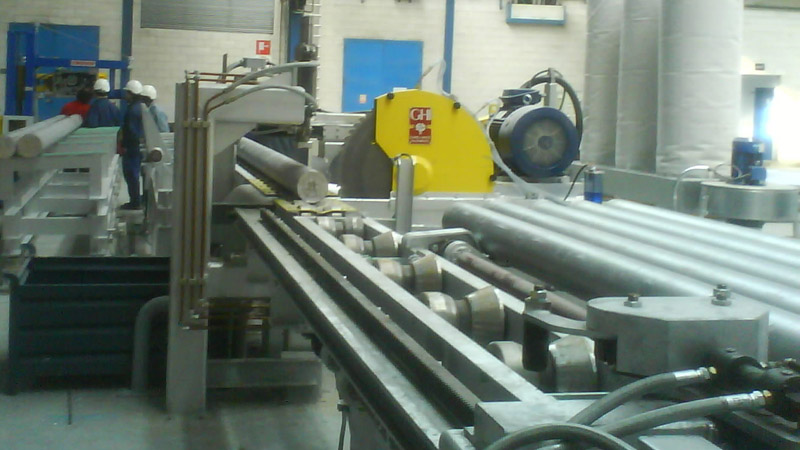

Cutting saws

After heat treatment, aluminium billets are moved to the cutting saw where the ends are trimmed and, if required, they are cut to measure for subsequent feeding into the extrusion press.

Operation

Saws can be equipped with additional devices for extracting and compacting the shavings produced, and with auxiliary equipment for weighing, marking and strapping the billets.

Value proposition

Precision cutting.

Optimised production time.

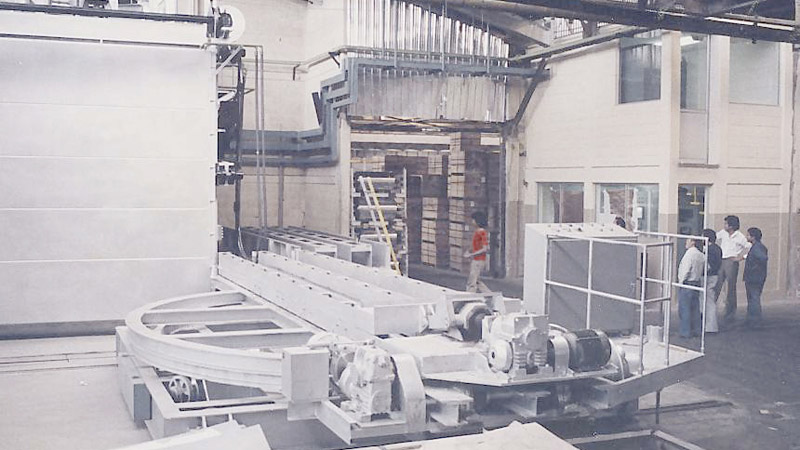

Casting machines

We have developed a wide range of vertical casting machines for both billets and sheets.

The casting machine comprises a rack for dies, a moving tray and a platform driven by a self-guiding cylinder, which bears the weight of the platform itself and the ingots being die cast.

Value proposition

Virtually maintenance-free.

Smooth movement of platform.

Vibration-free.

No surface marks on billets or sheets.

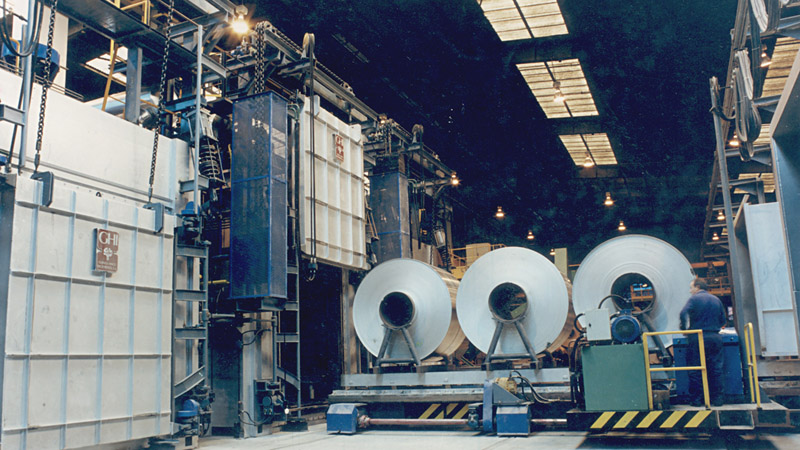

Aluminium scrap loading machines

At GHI, we have developed different types of loading machine adapted for aluminium melting and holding furnaces. They have been designed specifically for this application so that furnaces can be loaded quickly and efficiently and protected from impact or inappropriate manoeuvres. Energy losses and non-productive idle time in furnaces are also minimised.

Operation

The machines are mounted on a trolley which moves them along the length of the furnace door(s) being served. The pan containing the load is fitted with a guiding system and mechanism for inserting the load. A third mechanism takes care of pushing the load from the pan to inside the furnace. The movement of both mechanisms is synchronised so that the pan withdraws at the same time as the pusher moves forwards, and in this way the load is deposited on the furnace hearth in the same arrangement as it was loaded into the pan.

The pan is open at the front, which enables the scrap load to be positioned easily. Once the load is ready, the manoeuvre for unloading it into the furnace is coordinated with furnace door opening, and therefore the entire operation is performed quickly and efficiently.

Value proposition

Fully automated operation.

Prevents damage to furnaces, and use of equipment not specifically for the purpose.

Optimal furnace use and energy consumption through preventing downtime.

Reduced staffing costs.

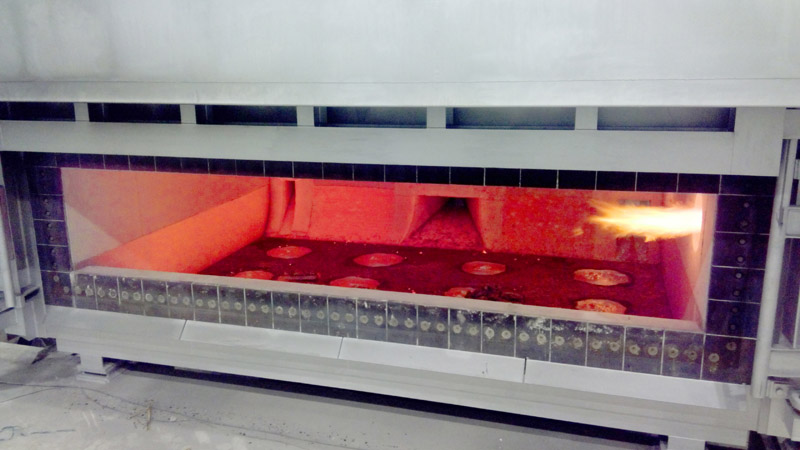

Drying – Decoating system

Operation

During the drying process, the load is heated up to 300 °C – 350 °C in order to remove water and oil. This process may be necessary even after a previous spin drying process to ensure the complete removal of moisture. For the decoating process, the load is heated up to 500°C – 550 °C, thus eliminating organic content by 80-90%.

Value proposition

Higher metal yield.

Lower energy consumption in the melting process.

Lower fumes emission.

Ingot casting machine

They are used for aluminium ingots manufacturing.

Operation

The liquid metal coming from the furnace enters the casting wheel where it gets distributed into each mold. Afterwards, the molds pass through a wind tunnel where they are cooled so that the ingots can be demoulded by the use of a knock-off system.

Value proposition

Ingot geometry uniformity

High efficiency.

Lower maintenance costs.