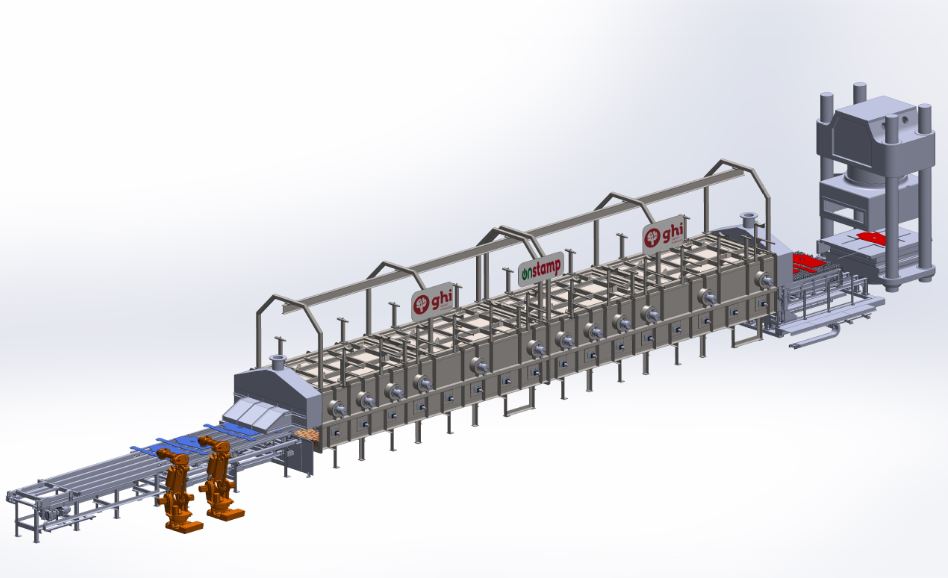

HORDAGO: Robust and efficient furnaces with advanced maintenance and availability for an optimized process management

Maximize the operational and energy performance with 4.0 technologies

The consortium formed by SIDENOR, NEMAK, FAGOR, GECSA, AVANGROUP supported by the agents of the RCVTI IK4-Ikerlan, University of Deusto, Edertek and Sidenor I + D has the goal of developing smart gas furnaces connected to 4.0 processes to maximize the operational and energy performance.

A greater robustness and efficiency in the equipment will not only reduce personnel and environmental risks but also it will improve the control over the furnace. Consequently, operating and energy costs will be saved during its useful life.

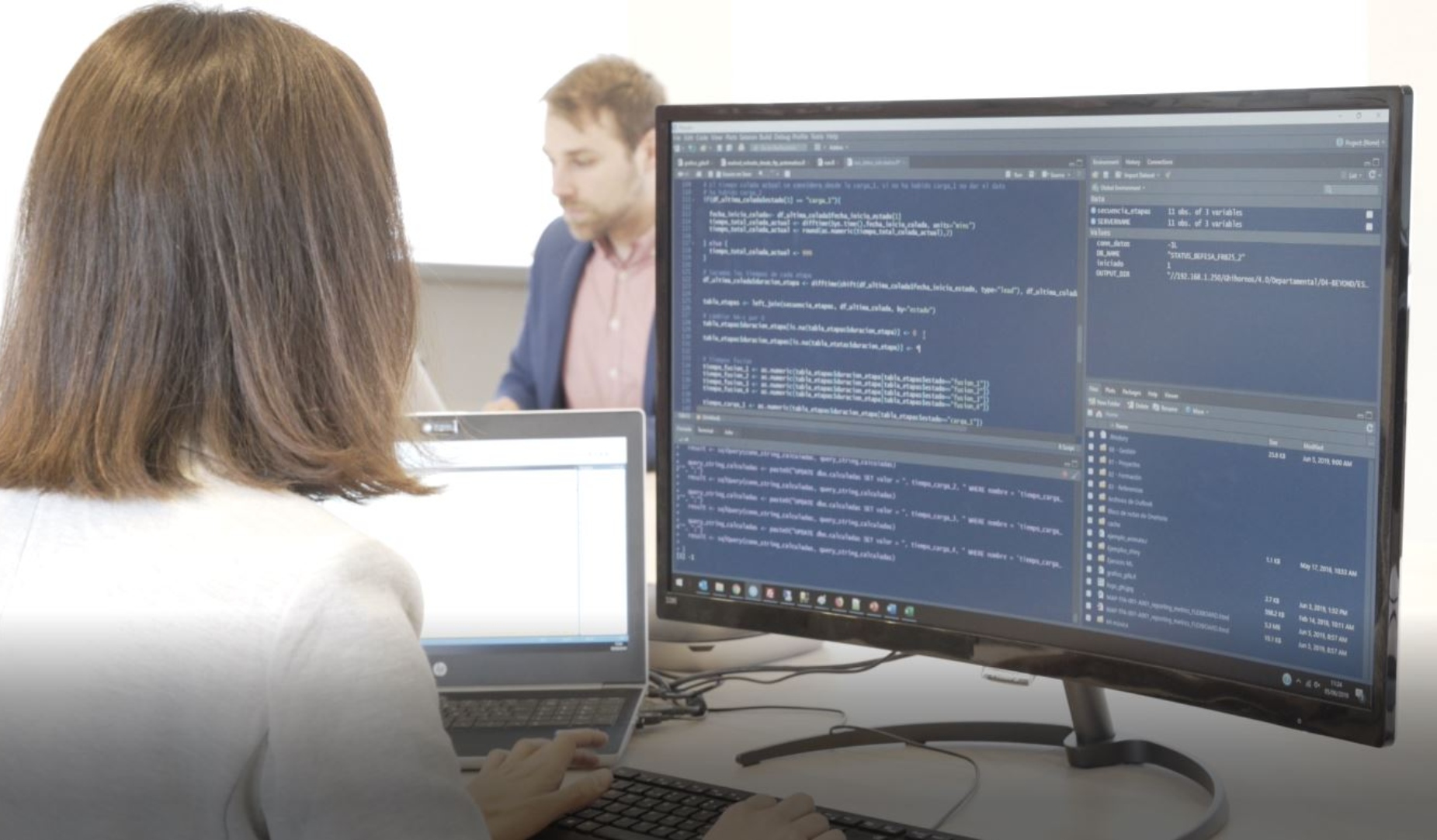

Thus, a virtual model will be developed, based on Big Data and Artificial Intelligence technologies, which will optimize decision-making that involves equipment maintenance and modernization strategies.

In addition, predictive models enable to prevent potential failures and to determinate production anomalies. As a result, the availability and efficiency levels of the 4.0 furnaces will be optimized.

This project, Hordago, has been co-financed by SPRI, Business Development Agency of the Basque Government

Financial entities