GHI completes a 20-furnace turnkey project for Metalogenia, worth 13 million euros

GHI Industrial Furnaces has designed, manufactured and placed in service a complete smelting and heat treatment plant for the new Metalogenia plant in Monzón, (Huesca, northern Spain), in an order worth 13 million euros for GHI.

Metalogenia, European leader in the excavation machinery adapters, protectors and attachment component market, has invested in backing continuous improvement and the R+D+i process, in order to obtain technology which enhances its customers’ productivity and performance.

The equipment, installed in a newly-constructed plant, is used to manufacture medium carbon, low alloy cast parts offering high resistance to wear and impact.

Smelting

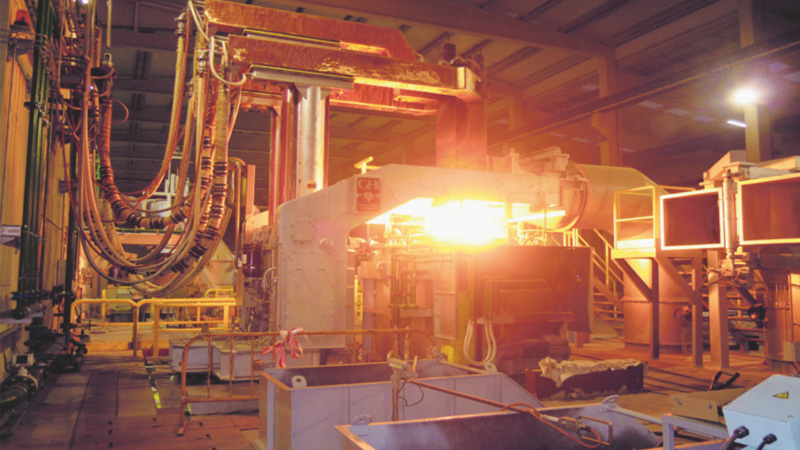

GHI has designed an 8-tonne capacity arc furnace, using the experience acquired during the manufacture of over 150 furnaces already supplied. It includes the latest technologies for transformers, conductor arms, hydraulic drives and devices for vault turning. It has an exclusive regulation and control system which optimises furnace operation and consumption of both electricity and electrodes.

The supply is completed with an oxygen convertor and auxiliary equipment such as loading baskets, electrode nippling station and ladle heaters, all of which are designed and manufactured by GHI.

As an essential part of the contract, GHI developed the general engineering for the plant, including general layout and shape and load plans for civil works.

Heat treatment plant

After the melting stage, parts undergo heat treating to give them the hardness and ductility properties necessary to withstand the tough working conditions in which they will be used.

For this purpose, GHI has designed a fully automated plant for the heat treating, austenitizing, tempering and quenching of parts. The only input required by the worker is to select the required treatment recipe, which is saved in the computer database. The rest of the process is carried out entirely automatically. The installation is also fitted with latest-generation thermography cameras which automatically measure the temperature of all processed parts.

GHI has equipped the installation with self-recuperative burners which combine good temperature uniformity low consumption of natural gas, thus improving plant productivity.

Both the smelting and heat treatment plants are fitted with sensor and data collection and transmission systems which enable GHI technology 4.0 to be implemented.