Plant for Recovering Aluminium from Dross

Total use of aluminium dross

At GHI, we design and supply plants for recycling and recovering aluminium from dross, including all the components required to ensure the efficient operation of such plants.

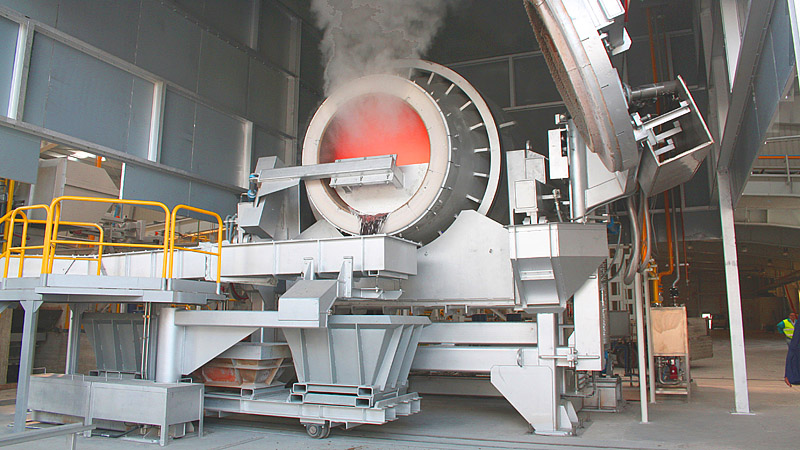

When aluminium is smelted, dross is produced that must be removed. This dross contains traces of aluminium that can be recovered by means of a subsequent melting process in a rotary furnace.

GHI supplies a specific range for aluminium refineries

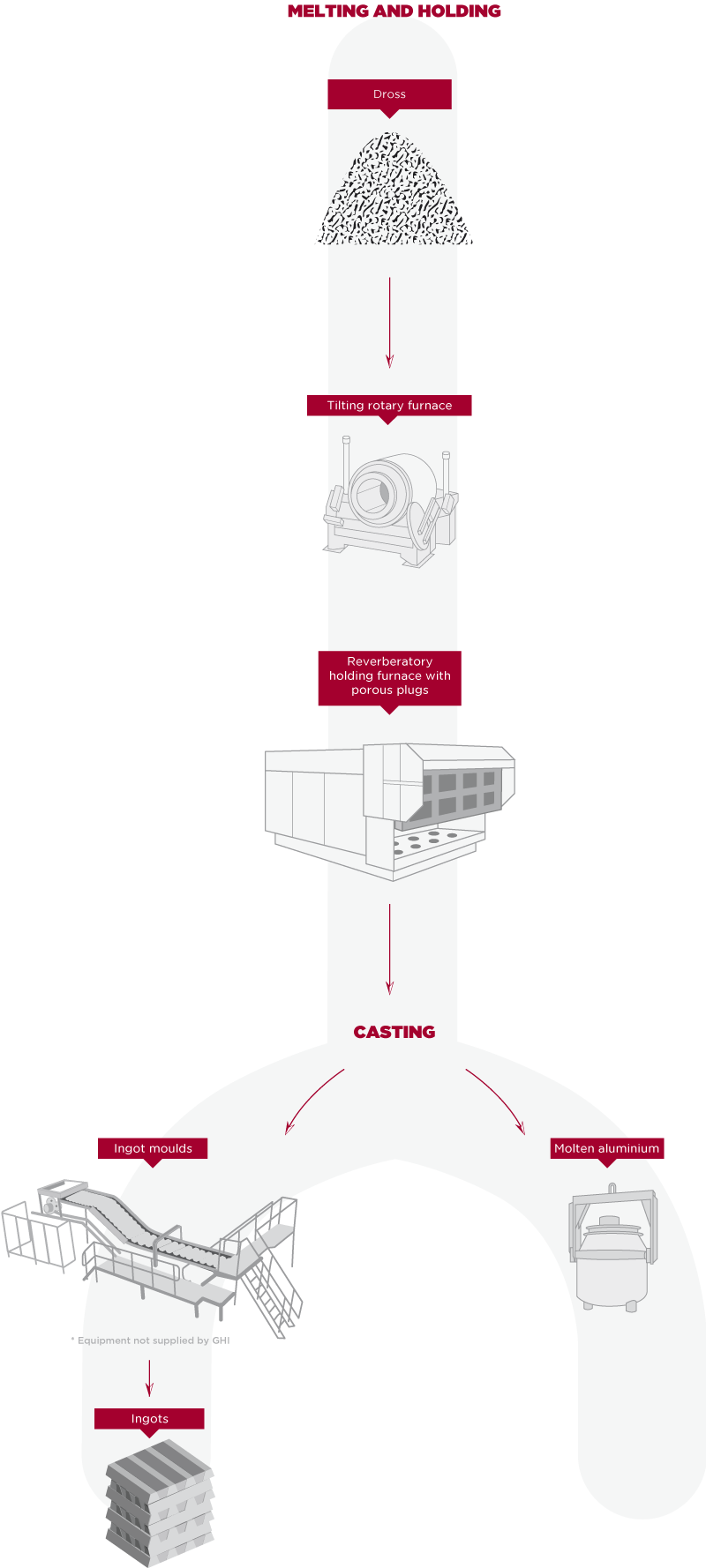

Dross containing aluminium is placed in a tilting rotary furnace, where the metal is smelted and then transferred to a holding furnace for addition of the alloying agents necessary. Finally, the alloyed metal is transferred to a casting machine for producing ingots, or poured directly into ladles for shipment by road in molten form.

GHI has developed a specific range of cutting-edge equipment for aluminium refineries. The aim is to recover aluminium from dross, supplying the market with customised aluminium alloys in both ingot and molten aluminium form.

Process for recovering aluminium from dross

The value proposition of this plant

Maximum recovery of aluminium contained in dross produced in smelting furnaces.

Quality and uniformity of the aluminium recovered, through an agitation system using porous plugs in holding furnaces.

Jointly engineered by all the stakeholders in the process, the aim being to find the solution that best meets the customer’s current and future needs.

Energy-efficient equipment.

A high degree of process automation permitting high production levels and minimum human involvement.

A management and control system which permits process variables to be monitored, thus offering possibilities for control and continuous improvement.

Corrective, preventive and predictive maintenance; SAT and Services 4.0.