COLD-HOT 4.0: New technologies of stamping 4.0 associated with new materials

COLD-HOT 4.0 aims to develop a new cold and hot stamping technology to meet the needs that arise in the market.

This project, developed in collaboration with the Gestamp Group and the technology centers Tecnalia, IK4 and Autotech Engineering, is divided into several lines of work:

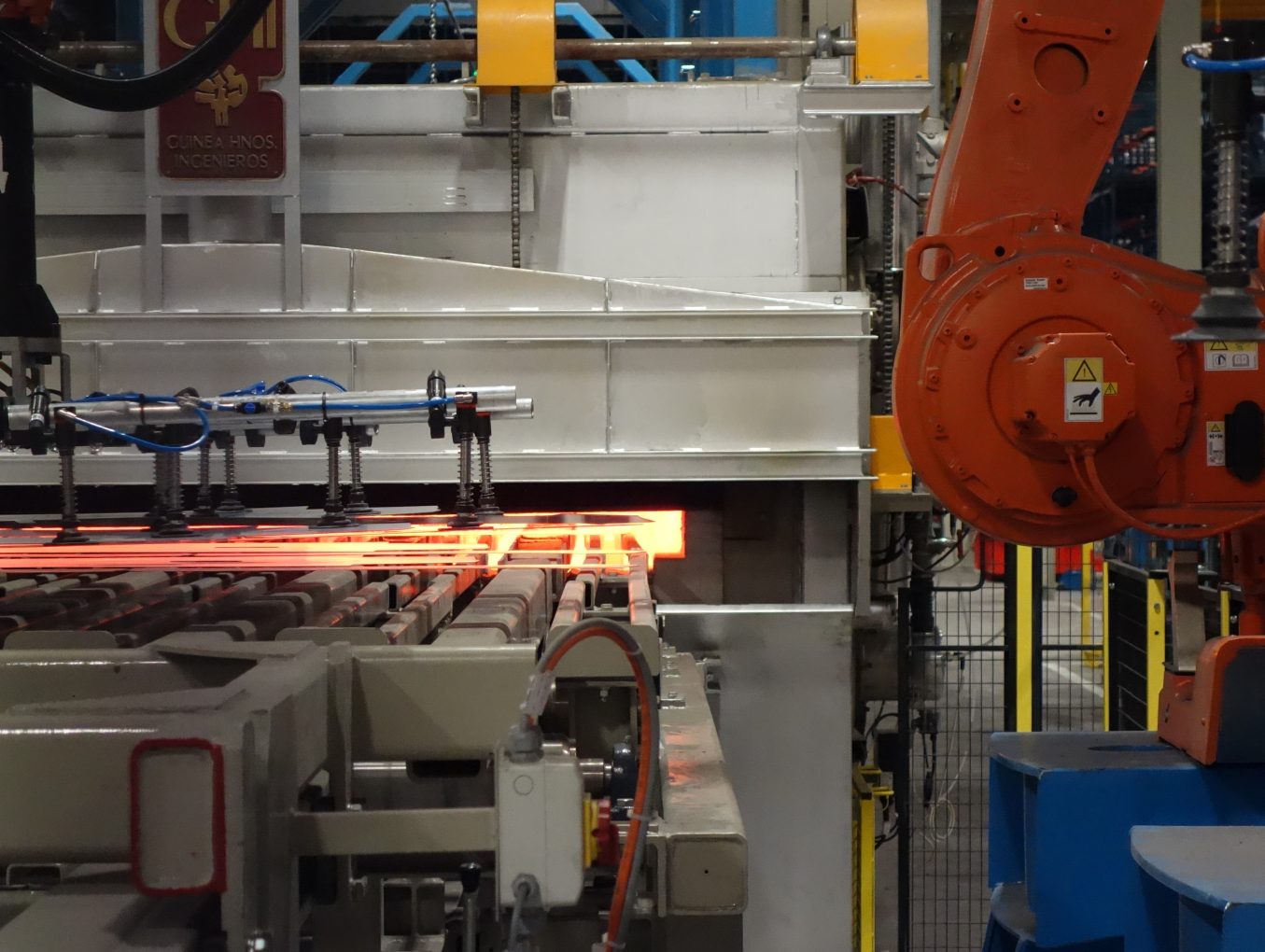

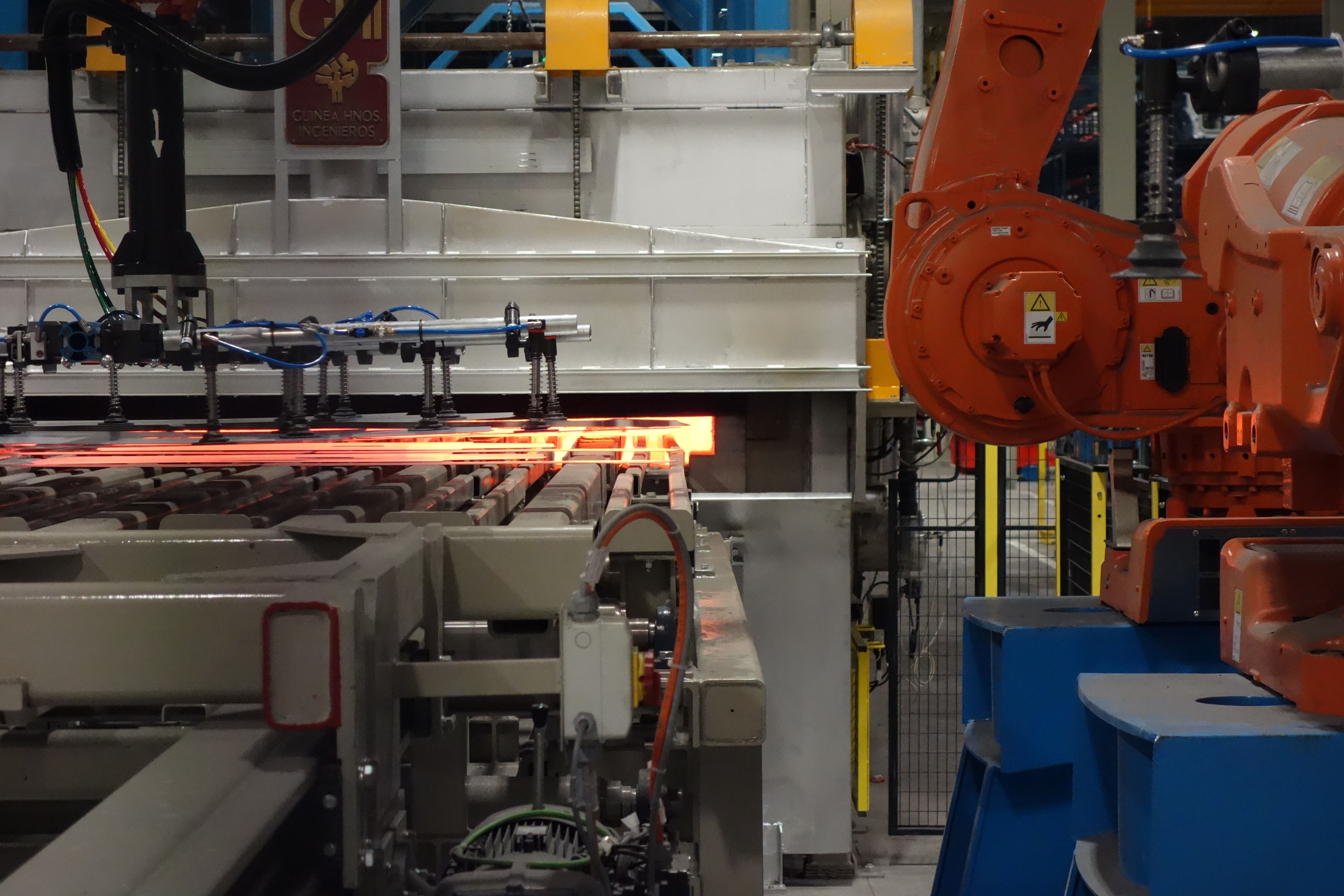

– Multistep: Development of a new material and hot stamping production process that allows to reduce the cycle time to 2-3 seconds.

– IPHS: Development of an improved indirect method of hot stamping that combines hot and cold deformation

– Softzone 2.0: Development of a hot stamping technology that allows to control the temperature in certain areas of the pieces to endow them with different mechanical properties

– Manufacturing 4.0: Development of a remote method of control and monitoring of the production process

– Cold line: Innovation in hydraulic presses to increase its cadence

This whole process of innovation has given rise to a new concept of hot stamping furnace that overcomes the traditional problems presented by roller hearth furnaces and that is currently in patent process..

This project, COLD-HOT 4.0, has been co-financed by the SPRI, Business Development Agency of the Basque Government.

Funding entities