Electromagnetic Vortex and Rotary Tilting Furnace of 50t for Fracsa, Mexico

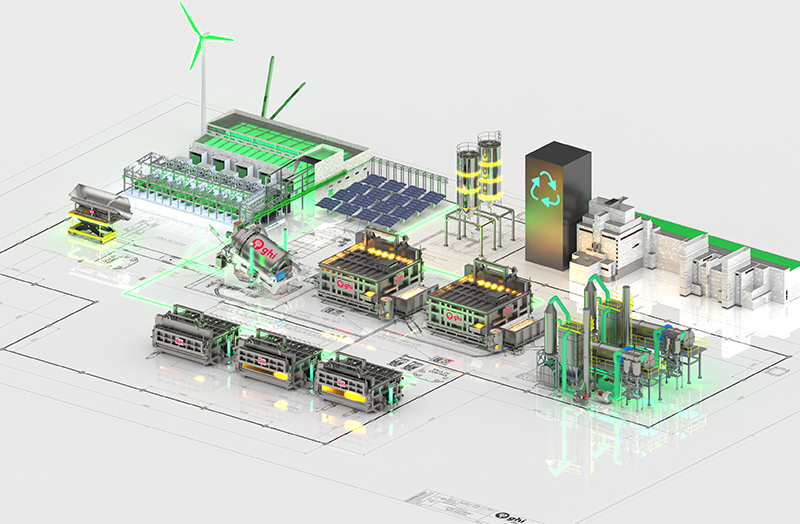

The result of an ambitious expansion plan to address the growing demand from the automotive sector in Mexico, GHI collaborated with Fracsa in the expansion of its aluminium recycling plant, by supplying two melting units for different types of aluminium scrap.

Integral solution

To be able to exploit all types of scrap we developed a 50-tonne rotary furnace, which has double the capacity of the largest piece of existing equipment of this type in the world. The furnace is designed to reach a maximum metallic performance together with minimum energy consumption, which strengthens our value proposal in the use of low consumption efficient technologies.

The configuration of the furnace and the integrated tilting system allow us to reduce the required amount of protective salts by 50% and facilitate the emptying and cleaning of the furnace, maintaining its capacity throughout its life cycle.

The second furnace, a Vortex type reverberatory furnace, specialized in the melting of aluminium shavings, chips or light scrap, is equipped with an electromagnetic pump that, in addition to achieving a significant level of recirculation of liquid aluminium inside the furnace, generates a vortex that allows for a rapid immersion of the load. It is the first melting furnace with this system to be installed in Mexico by GHI.

This system allows the rapid immersion of the load inside the molten metal, which avoids oxidation and consequently allows for high metallic performances in the melting to be achieved.

To improve the energy efficiency of the process, the furnace is equipped with state-of-the-art regenerative burners, which makes it an environmentally-friendly equipment, with low energy consumption and low emission of polluting gases into the atmosphere.

In addition, we are going to integrate our technology 4.0 into the equipment, which will provide the customer with better control over the production process as well as a greater reduction in the consumption of the installation.

Advantages

- Maximum metal yield along with minimum energy consumption

- 50% reduction in the required amount of protective salts in the rotary furnace

- Vortex furnace equipped with an electromagnetic pump and vortex that improves the quality of the molten aluminium

- Use of environmentally friendly latest generation regenerative burners

- Possibility of implementing technology 4.0

- Low emission of pollutant gases