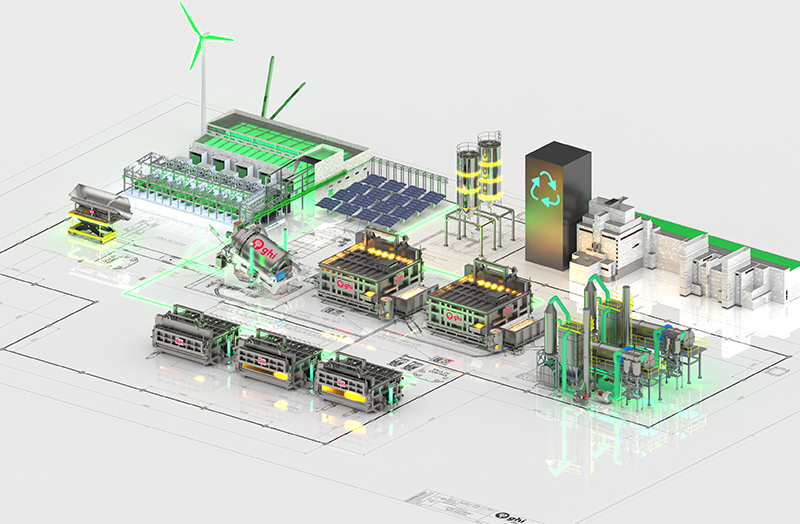

Smart plant for aluminium recycling

Befesa requested us for an integral solution for the meltting area of their aluminium recycling plant in Germany, in order to achieve better metallic performance with different types of scrap and dross.

Integral solution

After a consultancy process together with the customer, we developed a full turnkey plant with 7 furnaces for aluminium recycling. 3 tilting rotary furnaces for low quality scrap and dross, 1 Vortex furnace for light scrap such as chips and UBC, and 3 reverberatory furnaces with porous plugs to homogenize the temperature and the alloy.

The new aluminium recycling plant is the first Smart Plant in Europe for aluminium recycling and one of the most advanced thanks to our platform Beyond 4.0, which collects more than 1,500 variables per second, which are then analyzed by our engineering team, allowing us to optimize and continuously improve the control of the processes.

At GHI we are committed to the digitization of the plants to offer our customers a smart maintenance that provides them with better performance and productivity.

Advantages

- High level of automation and plant safety

- Monitoring of the operations in real time

- Remote identification and correction of anomalies

- Control and optimization of processes

- Optimization of production

- Recycling of all types of scrap or dross and high metal yield