Aluminium Coil Manufacturing Plant

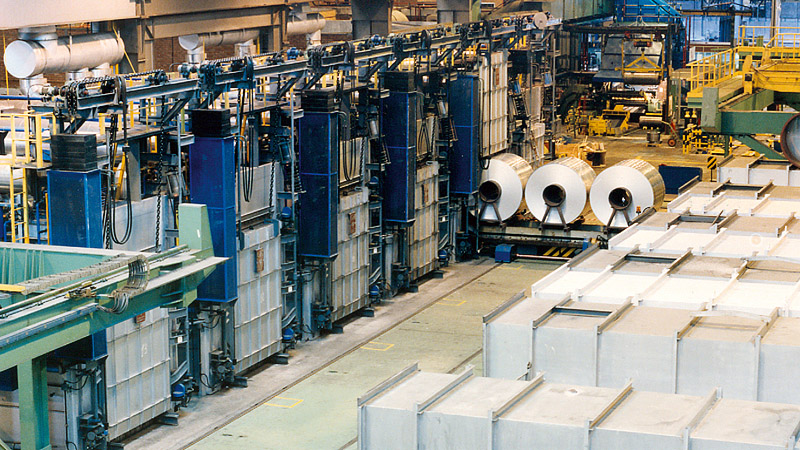

Types of plant for obtaining aluminium coils

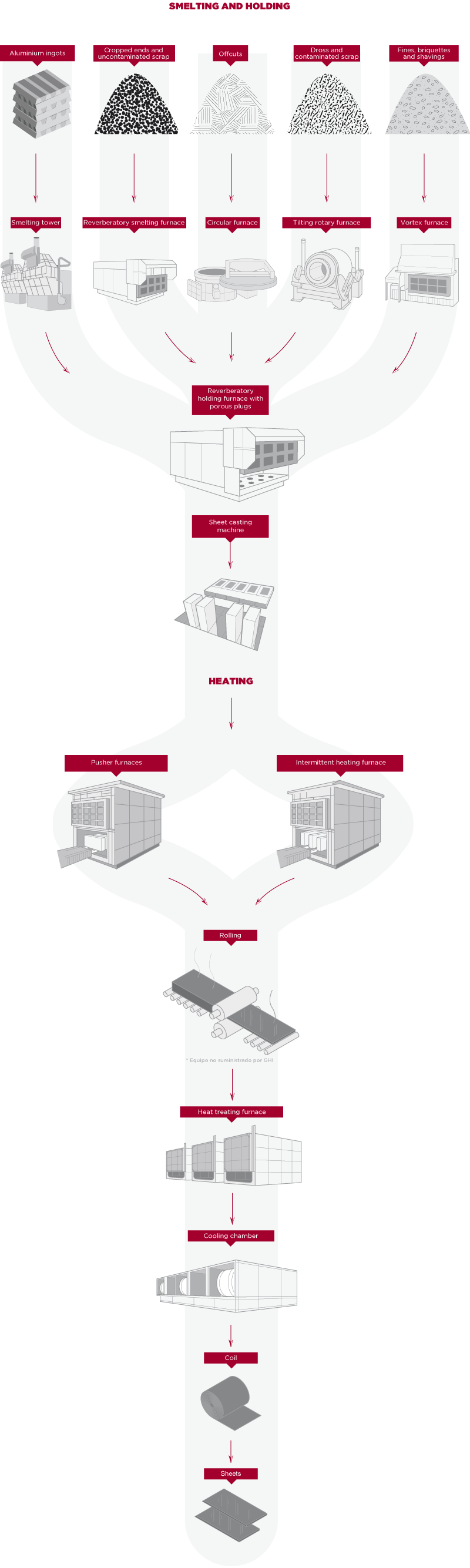

Aluminium coils can be obtained through a smelting process and adjustment of metal composition, either using a horizontal casting machine or by hot-rolling sheets obtained from a discontinuous vertical casting machine. At GHI, we design and supply the furnaces and auxiliary equipment used in the production process, during both smelting and treatment.

Continuous casting

Using molten primary aluminium, or by melting ingots and/or diverse scrap in the smelting furnace, the molten metal passes into a continuous casting machine where metal solidification and hot-rolling operations are combined.

The coils obtained in this way are then cold-rolled, following a number of intermediate annealing treatments.

At GHI, we design and supply the furnaces and auxiliary equipment used in the production process, during both smelting and treatment.

Plant certifications

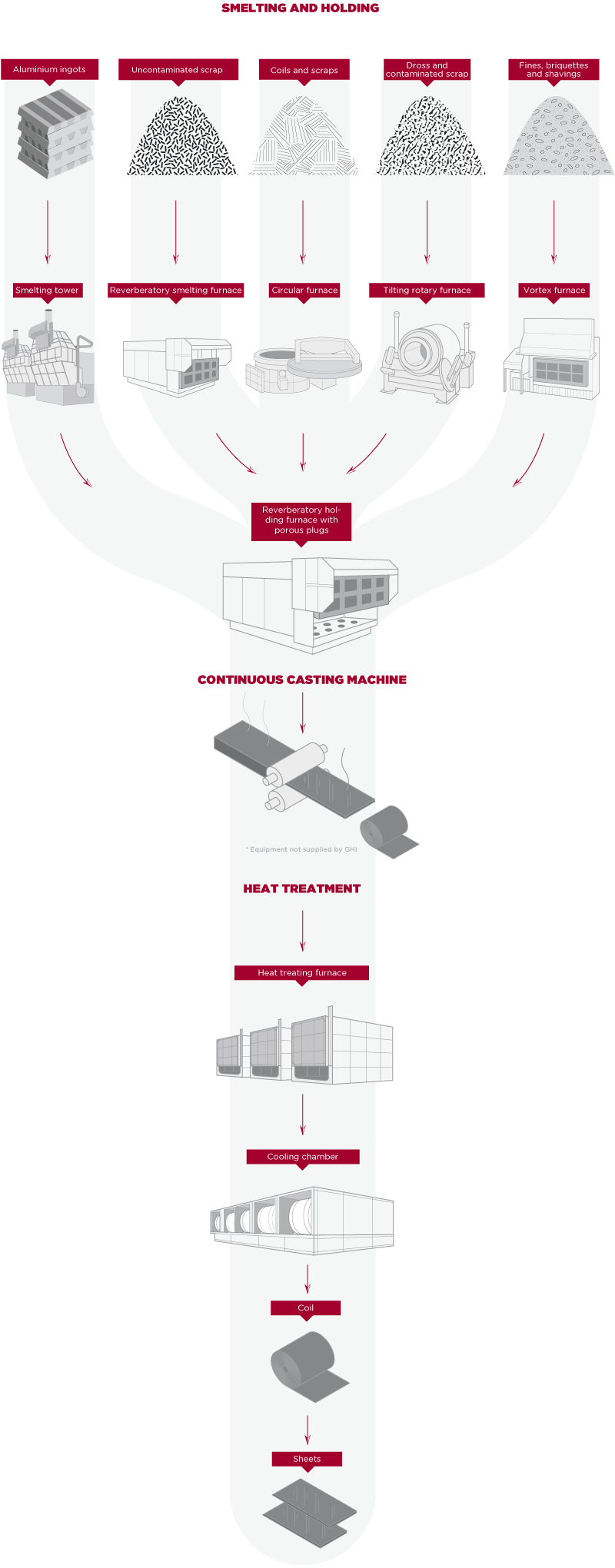

Continuous casting process for coil manufacture

Value proposition of this plant

Quality and uniformity of the aluminium recovered, through an agitation system using porous plugs or other systems in holding furnaces.

Jointly engineered by all the stakeholders in the process, the aim being to find the solution that best meets the customer’s current and future needs.

Energy-efficient equipment.

A high degree of process automation permitting high production levels and minimum human involvement.

A management and control system which permits process variables to be monitored, thus offering possibilities for control and continuous improvement.

Corrective, preventive and predictive maintenance; SAT and Services 4.0.

Equipment in this plant

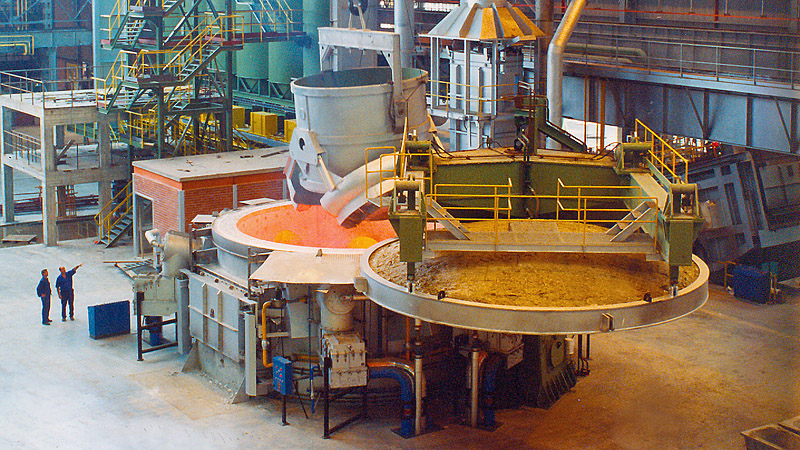

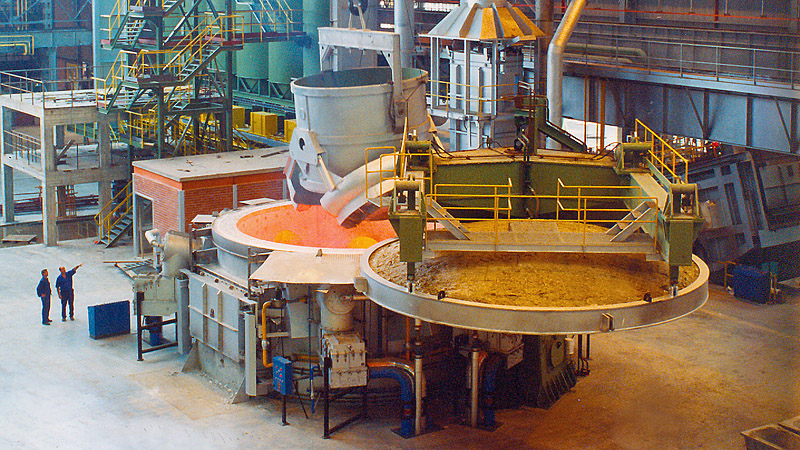

Smelting and holding process

Auxiliary equipment

Loading and unloading machine

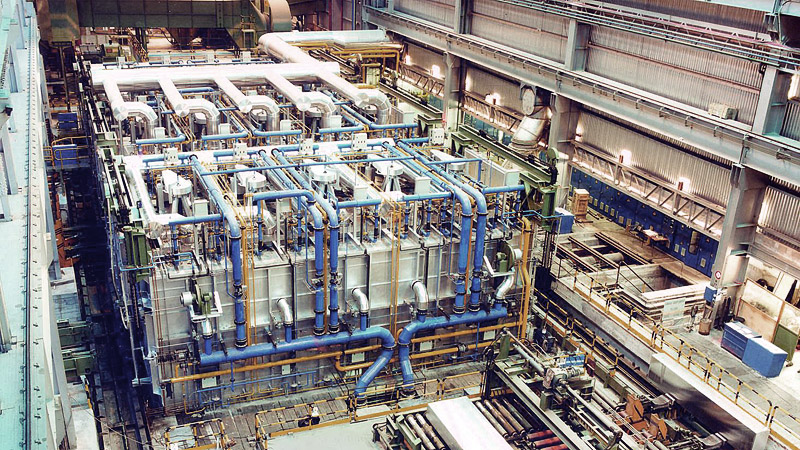

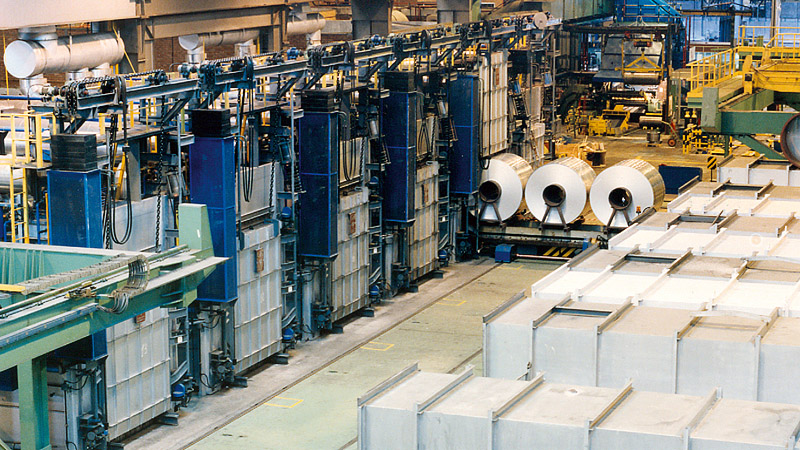

Discontinuous vertical casting

Using molten primary aluminium, or by melting ingots and/or diverse scrap in the smelting furnace, the molten metal passes into a discontinuous casting machine which produces sheets of different sizes. The sheets obtained are heated prior to being rolled into coils. Equipment for hot-rolling aluminium sheets and their alloys increasingly require strictly controlled conditions for the material to be rolled, in order to optimise the major investment represented by a hot-roller. The coils obtained in this way are then cold-rolled, following a number of intermediate annealing treatments.

At GHI, we design and supply the furnaces and auxiliary equipment used in the production process, during both smelting and treatment.

Plant certifications

Coil manufacturing process using discontinuous vertical casting

Value proposition of this plant

Optimises the investment in hot-roller.

Bulk melting of aluminium scrap and ingots.

High specific productions levels.

Quality and uniformity of the aluminium recovered, through an agitation system using porous plugs or other systems in holding furnaces.

Jointly engineered by all the stakeholders in the process, the aim being to find the solution that best meets the customer’s current and future needs.

A high degree of process automation permitting high production levels and minimum human involvement.

A management and control system which permits process variables to be monitored, thus offering possibilities for control and continuous improvement.

Corrective, preventive and predictive maintenance; GHI-SAT and GHI- 4.0 Services.