Manufacturing Plant for Cast Aluminium Parts

Modular design based on production level

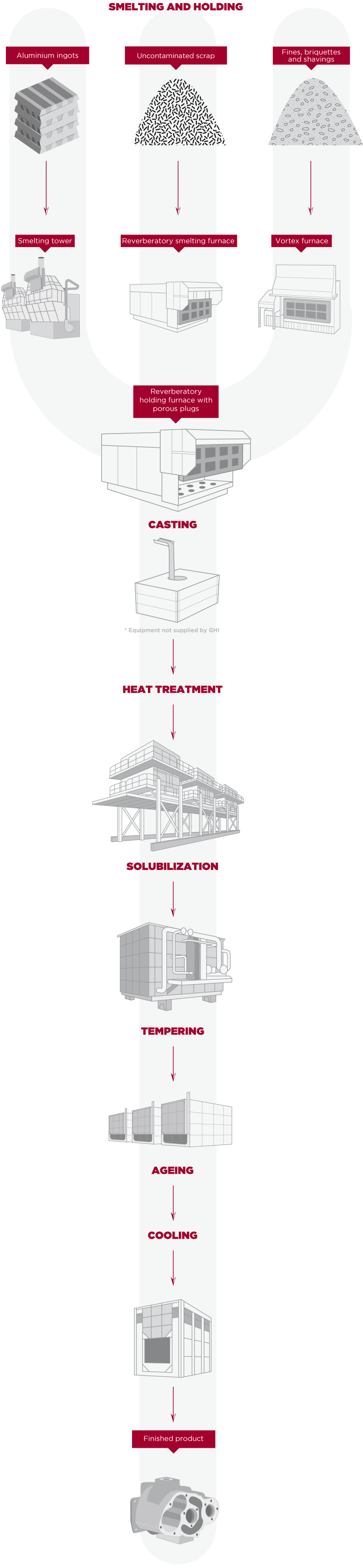

High-performance aluminium alloy parts used in critical applications are obtained through low pressure sand casting. Once the ingots have been melted and the parts produced in a low pressure casting machine, parts quality is checked and topping is done and then parts undergo solubilization, tempering and ageing treatments.

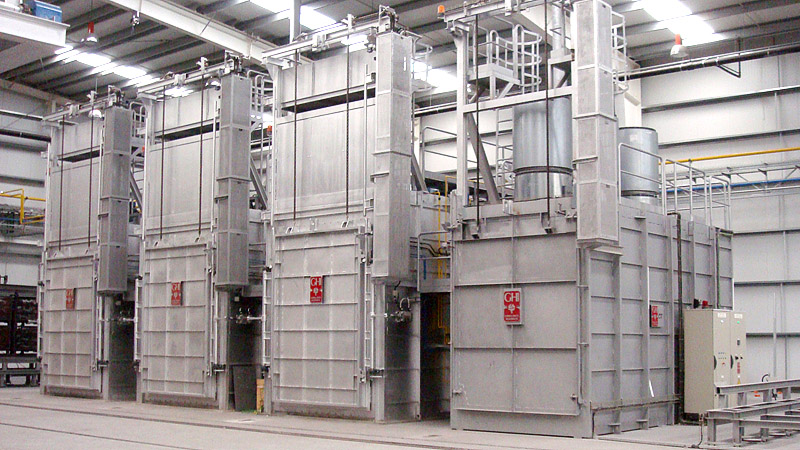

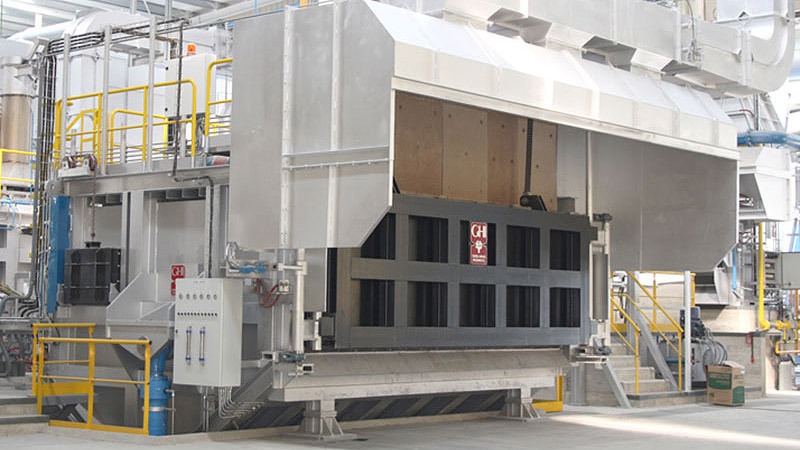

At GHI, we design and supply the furnaces and auxiliary equipment used in the production process, during both smelting and treatment.

Plant certifications

Cast parts manufacturing process

Value proposition of this plant

Modular design for installation, which through the addition of new furnaces permits gradual production increases.

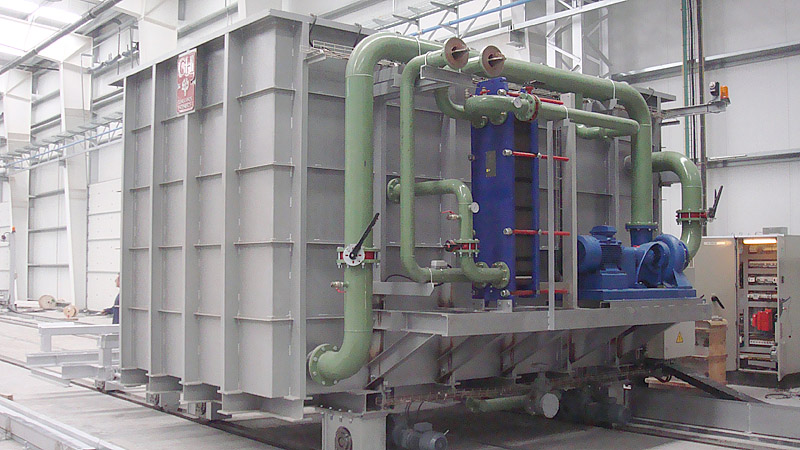

Quality and uniformity of the aluminium recovered, through an agitation system using porous plugs or other systems in holding furnaces.

Jointly engineered by all the stakeholders in the process, the aim being to find the solution that best meets the customer’s current and future needs.

Energy-efficient equipment.

A high degree of process automation permitting high production levels and minimum human involvement.

A management and control system which permits process variables to be monitored, thus offering possibilities for control and continuous improvement.

Compliance with requirements and certifications in aeronautical and automotive sectors.

Corrective, preventive and predictive maintenance; SAT and Services 4.0.