Turnkey Plants for Aluminium

Light alloys are key for the development of a large number of industries. In this area, GHI offers a wide range of complete plants to meet the growing demand for specific equipment for melting and treating aluminium.

Turnkey Plants for Aluminium

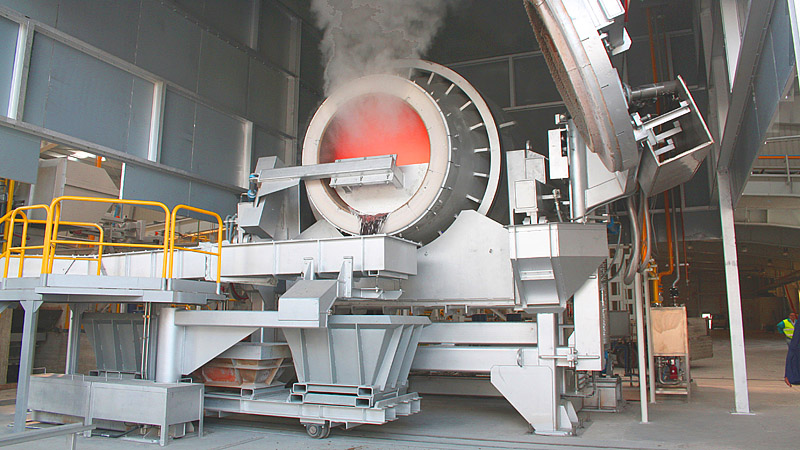

We design and supply plants and components for recycling and recovering aluminium from dross.

A specific range of equipment equipped with the latest technology for optimum use of processed aluminium waste.

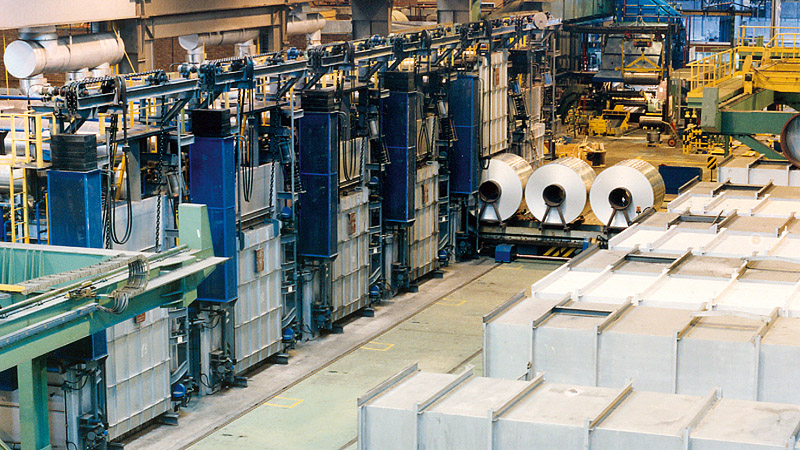

Billets of the size required are manufactured by melting down scrap, ingots, etc., and adjusting chemical composition.

Aluminium coils can be obtained through a melting process following by continuous or discontinuous casting.

We have responded to new demand by designing and installing plants for aluminium melting, casting and continuous rolling.

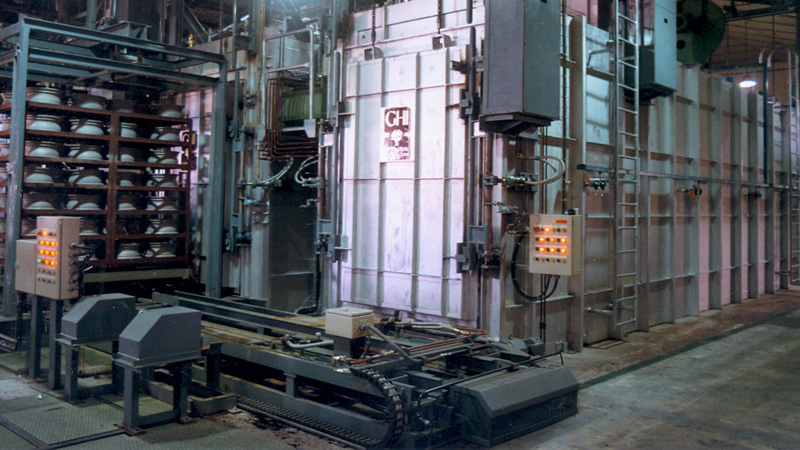

There are a number of stages: melting the metal, low-pressure casting, quality control, topping, heat treatment, machining and painting.

Low-pressure sand casting is used to obtain high-performance aluminium alloy parts.

Layout of automated heat treatment units for solubilizing and quenching parts used in the aeronautical industry.