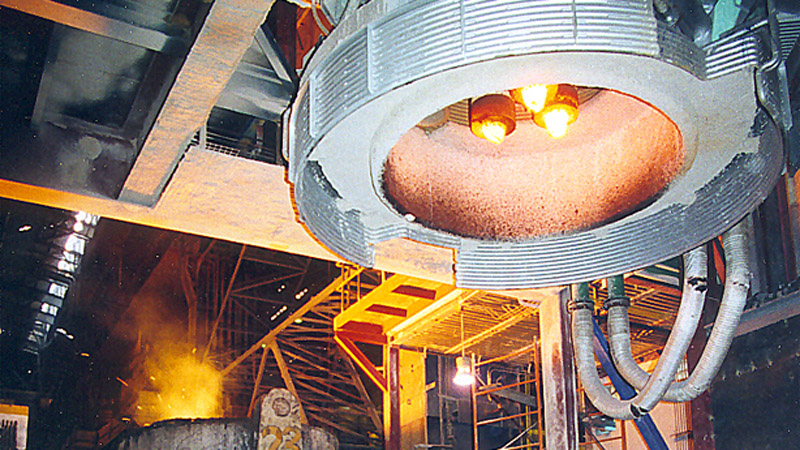

Ladle Furnace for Refining Iron and Steel

Improved steel quality

We design and build furnaces for refining molten steel and adjusting its chemical composition, with electric arc reheating of the metal contained in ladles. This is an essential process in metallurgical treatment, whereby the steel is refined and adjusted to the correct chemical composition and temperature before casting.

Two basic types of design

– Ladle furnace with fixed roof: the furnace has a fixed gantry and the ladle is mounted on a moving car. This is the type used in most medium and large size steelworks.

– Ladle furnace with swivelling roof: in this design, the ladle is lowered into the furnace by the casting crane. This means that in addition to raising and lowering movements, the roof must also be able to swivel.

Common features

– Reheating capacity of up to 5ºC/minute..

– Water-cooled tubular roof, gas exhaust extraction hood for inert or reducing atmospheres.

– Current conductive electrode arms.

– PLC automatic control and regulation system for electrode movements.

– High-intensity secondary circuit using water-cooled copper conductors.

Value proposition

Higher productivity.

Improved costs.

Improved, consistent quality of steelworks products.

Reduced tap-to-tap time and lower melting furnace casting temperature.

Increased efficiency of reducing refining, with higher ferroalloys yield.

Cleaner steels.

Even, controlled steel temperature.

Main features

| Capacity | Up to 180 tonnes |

| Heating rate degrees/minutes | Up to 5 |

| Configurations | Cylindrical |

| Types | Fixed or swivelling gantry |