Furnaces for Heat Treating Iron and Steel Bars

Flexibility to meet customer requirements

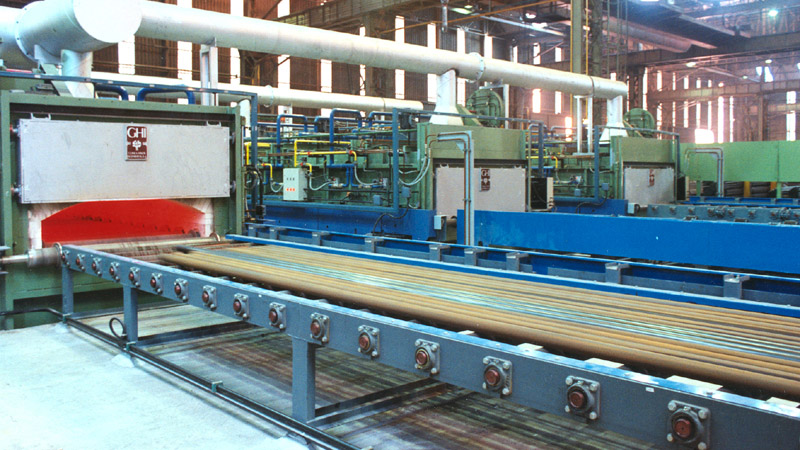

The installation comprises the loading table, furnace, cooling tanks, transfer device and cooling and unloading tables. Bars are moved along by rollers that rotate at automatically controlled speeds, enabling different heat treatment cycles to be performed.

The degree of automation is such that, once bars have been positioned on the loading table and the relevant code entered in the computer, the system performs all the operations required to move the load through the different pieces of equipment, perform the programmed treatment and deposit the load onto the unloading table, without any human involvement required.

Operation

The installation has been designed automatically to hold batch loads in the different stages of each treatment. All that is necessary is for the bars to be placed on the loading table and, on completion of process, removed from the loading table reception cradle. For this purpose, there is a computerised control system.

Installation components include different roller drives fitted with electronic frequency converters which enable different speeds to be selected.

Value proposition

High-precision temperature and uniformity across the entire load.

Fully automated installations.

Flexible configuration of heat treatments, according to customer requirements.

Minimum transfer time between furnace and cooling bath.

Certifications

Main features

| Capacity | According to customer requirements |

| Layouts | U-shaped or straight-line |

| Heating | Electric or gas |