Furnace for Heat Treating Forged Parts

High performance for forged parts

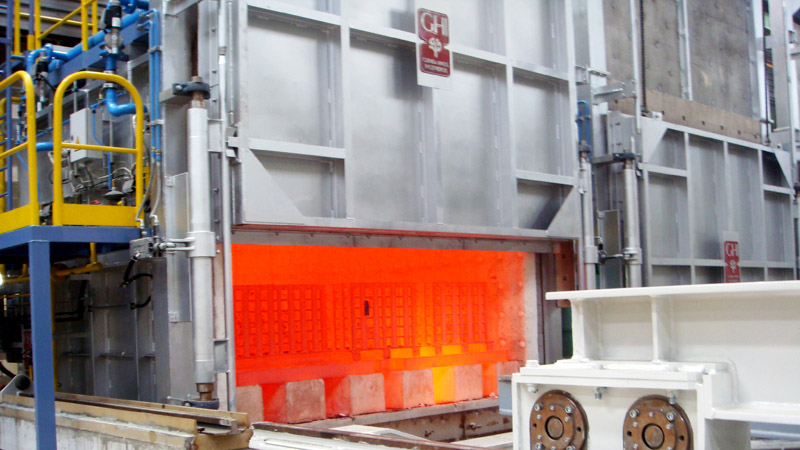

High-performance installation able to perform a wide range of heat treatments with minimum transfer time between furnace and cooling tank.

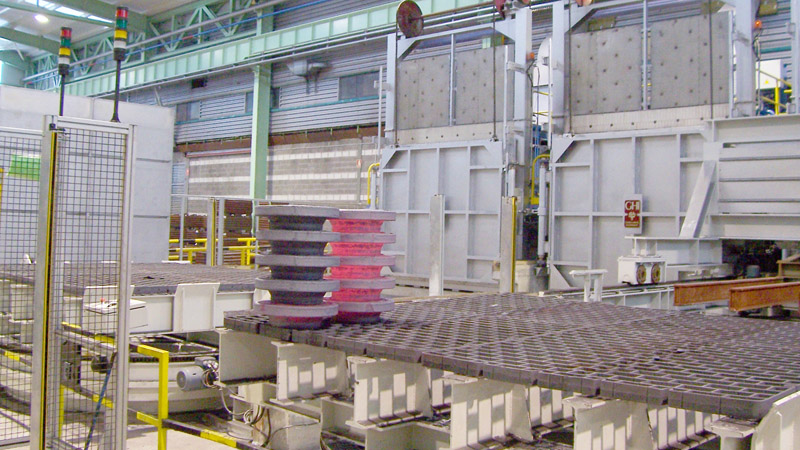

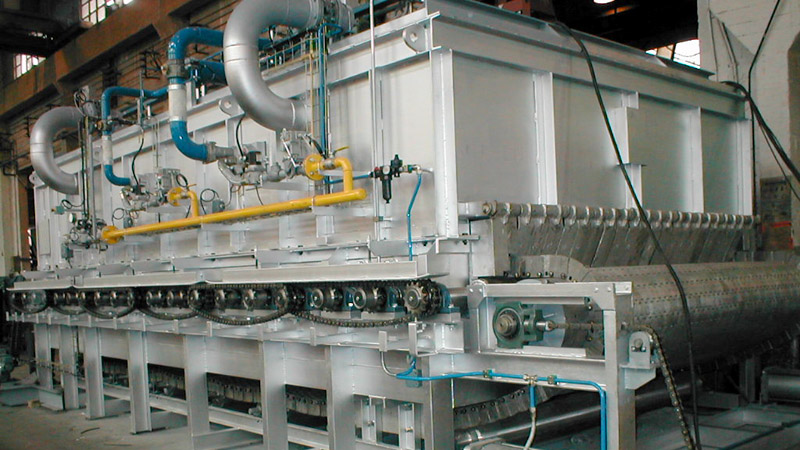

The installation comprises one or several identical or similar furnaces, loading and unloading tables, controlled cooling stations and machinery which, part by part or by complete load, moves them from the loading zones into the furnace chamber and, once the cycle has finished, leaves them in the unloading zone.

Operation

Furnaces cam be divided into two families depending on the system for introducing and extracting loads:

– Smooth hearth furnaces, where parts are introduced and extracted individually by a pincer device.

– Furnaces with hearths that have channels, along which the arms of a transfer device move to pick up and put down entire loads.

All processes are fully automated, unless the customer specifies otherwise. The system includes and executes the sequences and cycles required to achieve the desired treatment. Similarly, all operations are monitored and data recorded for the purpose of quality control traceability.

Value proposition

High-precision temperature and evenness across entire load.

Fully automated installations.

Flexible configuration of heat treatments to meet customer requirements.

Minimum transfer time between furnace and cooling bath.

Installation can be expanded by addition of modules..

Certifications

Main features

| Capacity | According to customer requirements |

| Layouts | “U” or “in-line” |

| Heating | Electric or gas |