Heat Treatment Furnace for Die-Cast Parts

Curing and solubilizing die-cast parts in raised chamber

Heat treatment of aluminium die-cast parts has two different treatments during manufacture:

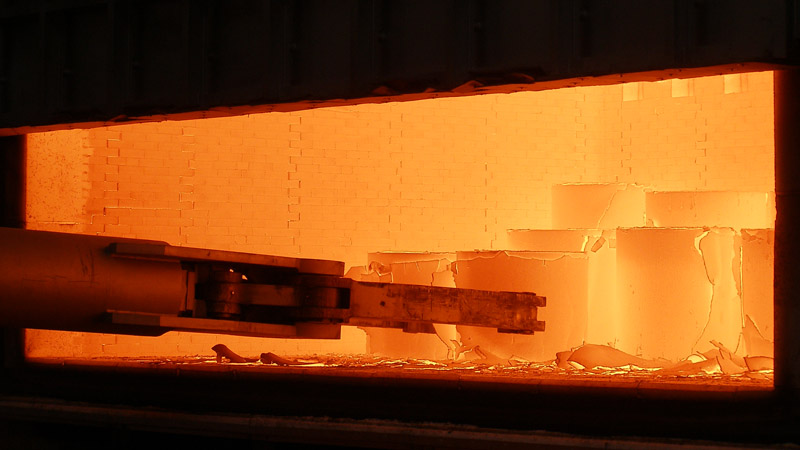

Die-cast parts furnace

In die casting of aluminium parts, there needs to be a curing treatment following solubilization and quenching. The parts for treatment are loaded into containers which are grouped together and stacked, and then placed in the furnace.

GHI supplies specific types of furnace for this application. They are fitted with powerful fans located at the top of the chamber which circulate the atmosphere inside the furnace after it has passed over heating elements. They are horizontal chamber furnaces with a machine for transferring material between the intake point from solubilizing and quenching treatments, furnaces, and other components such as cooling chambers.

Value proposition

Better mechanical properties can be obtained in parts.

Rapid, uniform heating, complying with applicable standards.

Automated installations.

Smaller workforce required.

Certifications

Main features

| Capacity | Up to 10 tonnes |

| Heating | Gas or electric |

Associated equipment

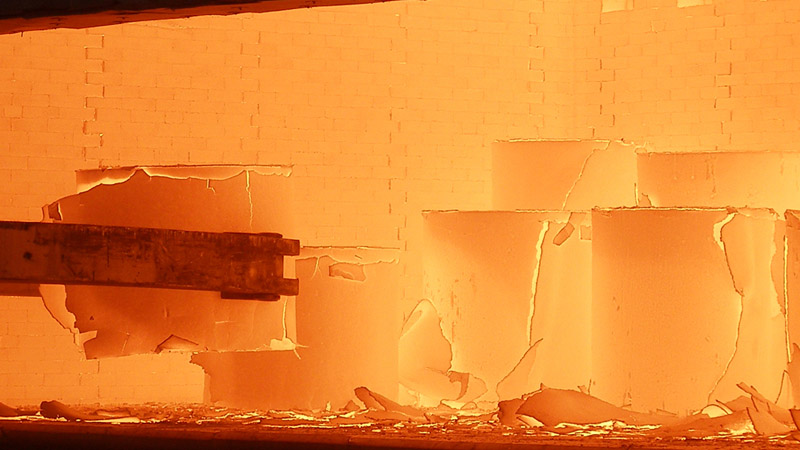

Raised chamber furnace for die-cast parts

At GHI, we have developed a specific type of heat treatment furnace for solubilizing die-cast aluminium parts prior to quenching. This process is extraordinarily demanding as regards treatment temperature uniformity and transfer time between furnace and cooling bath. The parts for treatment are placed in baskets which are positioned inside the furnace during the heat treatment process.

For these reasons, the furnace is designed with a raised chamber and rapid-action doors, a mechanism for raising and lowering loads, and a quenching tank located below the chamber. It has a high-capacity atmosphere circulation system and a high-precision temperature regulation system, thus complying with the stringent certification standards currently applicable in both the aeronautical and automotive sectors. Multiple furnaces are usually served by a single quenching tank, since the latter has a far lower occupation rate than the furnaces.

Value proposition

Complies with temperature precision certification standards.

Multiple furnaces can be fed by a single load transfer system.

Fully automated installations.

Modular design.

Certifications

Main features

| Capacity | Up to 10 tonnes |

| Heating | Gas or electric |