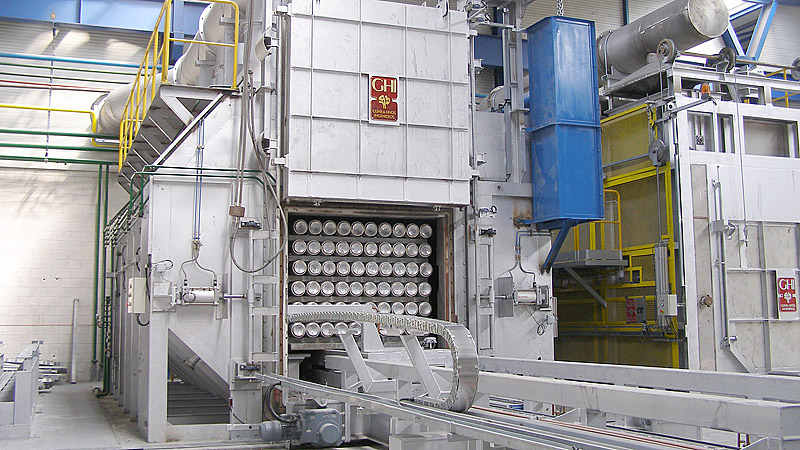

Aluminium Billet Heat Treatment Furnace

Heating uniformity and speed

The billets obtained in foundry casting machines undergo homogenization treatment to improve their mechanical and metallurgical properties.

For this purpose, furnaces are used which are loaded by several external machines. These types of furnace offer the advantage that only the load absorbs heat inside the furnace, since there are no supports or trolleys that are heated up and cooled down with the load, which means energy loss that makes treatment slower and more expensive.

They operate completely automatically from reception of load, billet by billet, to delivery in stacks of billets cut to required size and strapped if a load holding system specifically for this purpose has been designed and installed.

Value proposition

Automated operation integrated with the automated holding system.

Installation flexibility, since it can easily be expanded.

High temperature uniformity provided by uniform hot gas flow which circulates around billets on all layers.

Rapid, uniform heating of billets to the required treatment temperature.

Certifications

Main features

| Capacity | Up to 80 tonnes |

| Layouts | In one or two lines with reversible loading machine |

| Load length | From 3 to 8.5 metres |

| Heating | gas or electric |